Ultra-High Vacuum optical encoders

Maintain clean high-vacuum environments and minimise outgassing

All products in Renishaw's range of UHV compatible encoders are designed for use in a variety of scientific, semiconductor and other advanced industrial applications with vacuum pressures to 10-10Torr.

The fundamental principles of operation are the same as those for our equivalent standard-atmosphere products, but the UHV variants are designed to eliminate unvented voids and are specially constructed from clean, vacuum-compatible materials and adhesives. The suitability of the products for use in UHV environments is qualified by an independent specialist test house, including a Residual Gas Analysis (RGA) spectrum test (available on request).

The range includes incremental and absolute, open optical encoders.

There are many high-quality encoder products on the market, but few are also compatible with vacuum applications. Renishaw's TONiC UHV encoder delivers both excellent performance and reliability, it is our best choice.

VAD Instruments, South Korea

Incremental UHV encoders

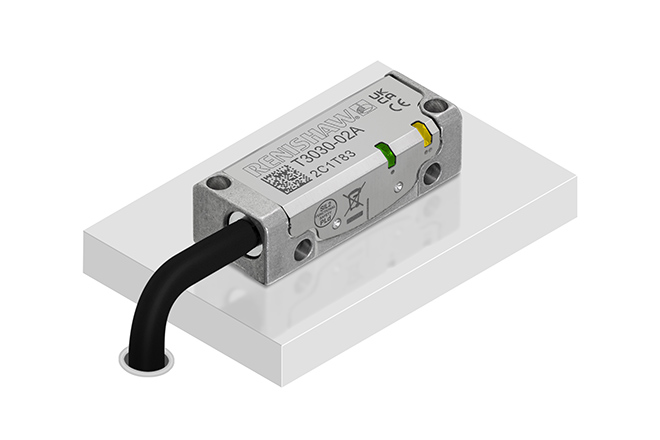

TONiC™ UHV open encoder systems

The TONiC UHV encoder is a specially modified variant of the TONiC encoder series. It offers:

- Compatibility with a range of scales:

- Linear: RTLC stainless steel tape, RKLC narrow stainless steel tape, RELM ZeroMet spar, RSLM stainless steel spar.

- Rotary (angle): RESM stainless steel ring, REXM ultra-high accuracy stainless steel ring.

Absolute UHV encoders

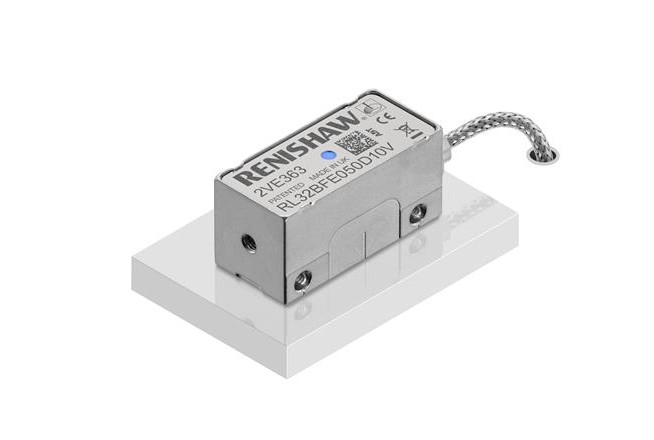

RESOLUTE™ UHV open encoder systems

The RESOLUTE UHV encoder is a specially modified variant of the RESOLUTE encoder series. It offers:

- BiSS® C and Panasonic serial interfaces.

- Compatibility with a range of scales:

- Linear: RTLA stainless steel tape, RELA ZeroMet spar, RSLA stainless steel spar.

- Rotary (angle): RESA stainless steel ring, REXA ultra-high accuracy stainless steel ring.

Watch our introduction to RESOLUTE absolute UHV encoders

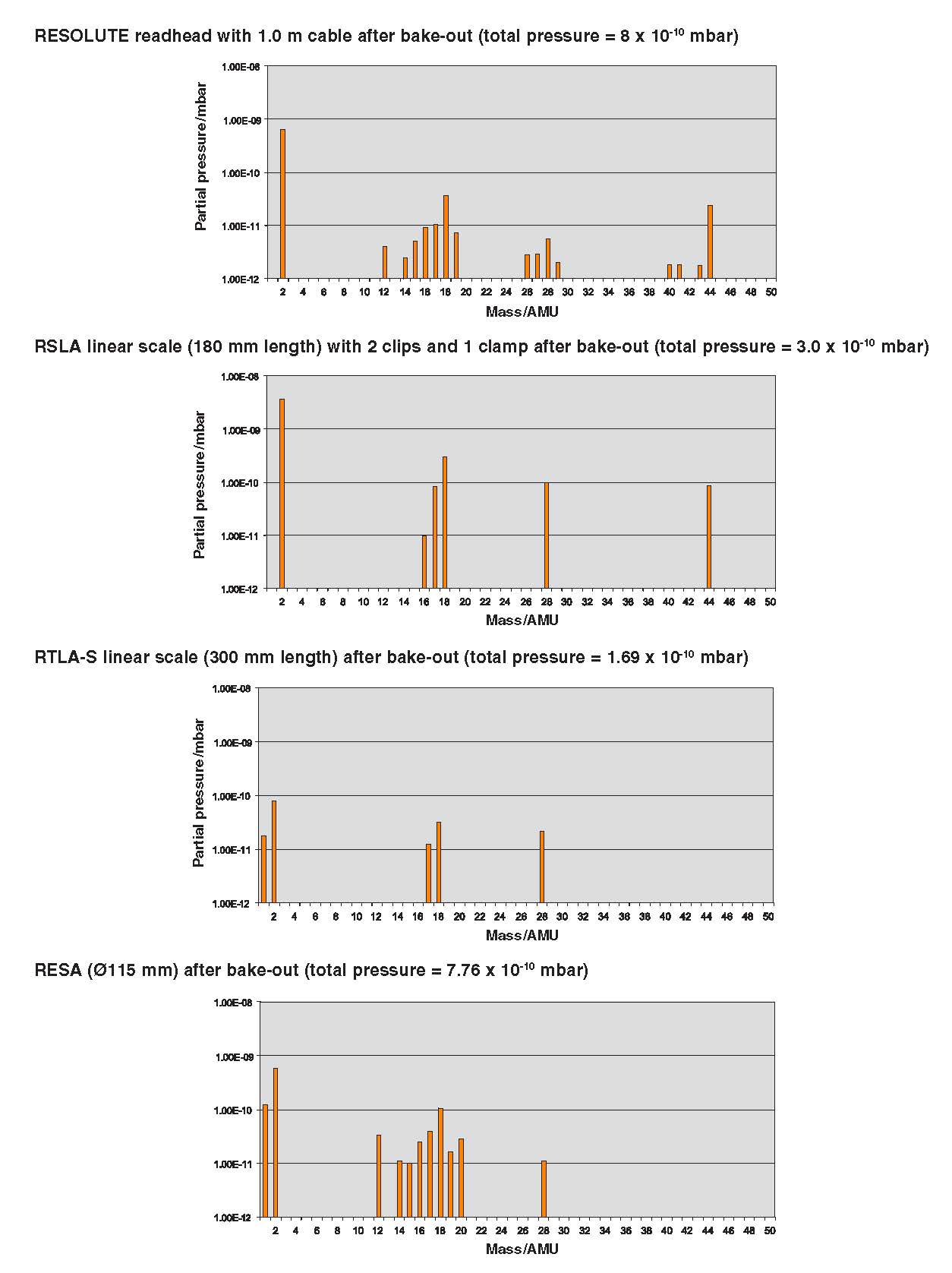

RGA results for RESOLUTE UHV encoders

Renishaw offers RGA (residual gas analysis) data for various RESOLUTE vacuum systems. This shows the effect the encoder system has on a vacuum environment.

RGA results

Test schedule

A quadrupole mass spectrometer (AccuQuad 200 RGA) was used to collect RGA (residual gas analysis) data. Chamber pressure was measured with an Ion Gauge (G8130). After initial conditioning of the system, a background spectrum was recorded together with the total pressure in the test chamber.

The component was placed in the vacuum system (0.0035 m3) which was then pumped using an KJL Lion 802 (800/s) diode ion pump and a Divac diaphragm pump at ambient temperature for 24 hours, after which a background scan and the total pressure in the test chamber were recorded again. If the system pressure was better than 5 x 10-9 mbar, the test specimen was baked at 120 °C for 48 hours. The system was then allowed to cool to ambient temperature before a final mass spectrum and total pressure measurement were taken. The final RGA scans are shown below.

NOTE:

Exact reproduction of these results should not be expected, as RGA data depends on the condition, specification and performance of the vacuum system. However, the Residual Gas Analysis results test shows no significant contamination attributable to RESOLUTE UHV and that UHV conditions can be achieved in the presence of this product.