Alignment lasers for machine build

What is an alignment laser?

An alignment laser is a precision tool that utilises lasers to accurately align components during build and service of industrial machines such as machine tools, precision stages and semiconductor manufacturing machines. Designed to optimise performance, alignment lasers facilitate high-accuracy measurement, digital reporting and real-time axis adjustments.

The increasing demand for intuitive tools to streamline machine alignment processes has outpaced the effectiveness of many traditional methods.

The XK10 alignment laser system offers digital precision for aligning both linear and rotary axes, presenting a modern upgrade from traditional manual methods. This leads to a significant reduction in machine build, maintenance and service time.

The XK20 alignment laser system is our second generation alignment laser system specifically designed to make machine build easier, faster and in conformance to the latest ISO standards. This helps to ensure high accuracy, durability and reduce operator error.

Why would you use an alignment laser?

is crucial to ensure precision during construction of a machine tool to make sure that it is reliable and efficient. Checking the alignment during the build process can prevent errors from being discovered after the machine has been built, which can be more difficult to fix. Regular alignment checks are also valuable during on-site service, maintenance or following a collision.

Our alignment laser systems provide a quick, easy and versatile alternative to traditional methods, like dial gauges, autocollimators and metrology artefacts. They eliminate the need for time-consuming procedures. Alignment lasers can be used to ensure that linear rails are straight, square, flat, parallel and level. They can also assess spindle direction and coaxiality of rotary machines.

The display units digitally records measurements, providing comprehensive error reports and reducing operator error due to manual documentation.

Key benefits

Easy to use

Guided step-by-step measurements reduce the need for highly skilled operators.

Multi-faceted

Measures rotary axes, spindles and facilitates precision during installation and automation.

Live readings

Instant view of live readings results and dynamic graphs for efficient alignment and measurement.

Detailed results

Straightness and parallelism analysis in the CARTO software Explore application, provides insightful actionable results.

Introducing our XK20 alignment laser system

Build to international standards

At Renishaw we recognise our customers' growing need to simplify and de-skill the measurements required during machine assembly. Leveraging over 50 years of machine tool industry expertise, our advanced XK20 alignment laser system technology meets the challenges faced by modern machine builders.

The XK20 system is our second-generation alignment laser system. It delivers unmatched precision, performance and traceability while complying with ISO accuracy and reporting standards 230-11. Renishaw's innovative CARTO XK20 app includes ISO 10791 and 3070 compliant measurement tolerances.

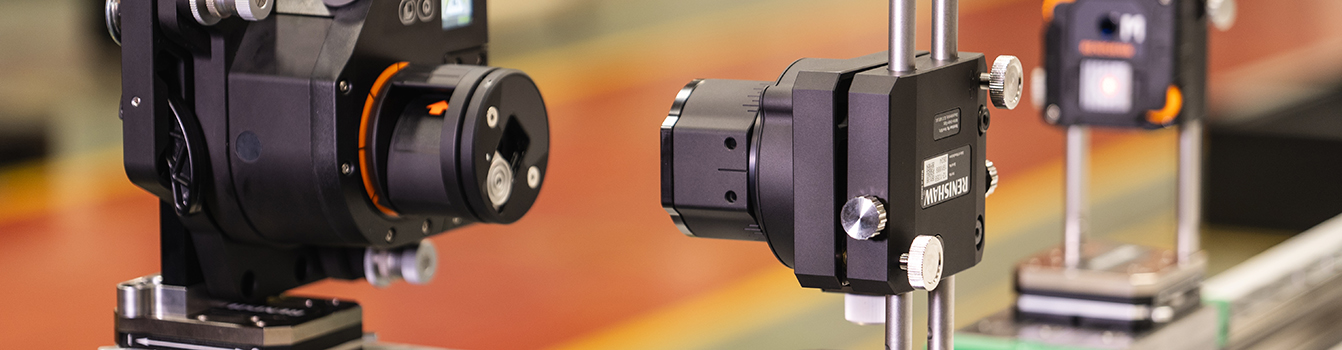

Launch unit

The launch unit is the laser reference of the XK20 system. It has a built-in calibrated pentaprism, precision rotating head, and digital levels. This provides a stable reference for straightness, parallelism, squareness and flatness measurements. It can also be used for levelling machines and castings.

Key features:

- Digital precision levels

- Smooth 360 head rotation

- Over 12 hours continuous operation

- Rechargeable battery

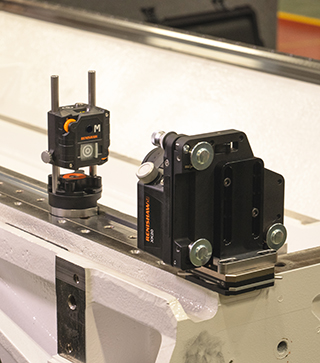

Moving unit (M unit)

The M unit is the primary sensor for the majority of XK20 system measurements. Similar to the principle of mounting traditional dial indicators on the axes or carriages being measured, the M unit detects deviations from the laser reference and sends a digital record to the CARTO XK20 app for analysis.

Key features:

- 2-axis PSD sensor

- Wireless connectivity to the CARTO XK20 app

- Over 12 hours continuous operation

- Rechargeable battery

CARTO XK20 app

The CARTO XK20 app builds on the strengths of Renishaw's CARTO calibration software to deliver a sequential and intuitive user experience to aid both skilled and unskilled machine tool builders and assembly operators.

Using the CARTO XK20 app with the XK20 alignment laser system makes the measurement process more manageable, enabling large and complex machine structures to be assembled and aligned faster. It consolidates the number of steps needed to perform measurements, simplifies user interaction and increases throughput, ensuring the highest level of accuracy and traceability.

Mobile app

Developed specifically for machine builders, the CARTO XK20 app is ideal for factory environments. Available on Android™ devices, operators can easily use the app to optimise their measurement and assembly processes.

Built-in guidance

The XK20 alignment laser and the CARTO XK20 app require minimal user training. The app's built-in guide is designed to be accessible to both skilled and unskilled users, with step-by-step instructions including images and illustrations.

Easy set-up

Aligning the laser to the workpiece or machine is crucial before taking measurements and can be time-consuming, especially over long distances. The CARTO XK20 app simplifies this task, making it faster and easier to use.

Data analysis

Data analysis can be tailored to user needs, for example:

- view error graphs quickly with customer tolerances

- download raw data for research and development analysis

- report configured results in various ISO formats.

Key measurements

The XK20 alignment laser focuses on key measurements needed for building medium to large machines, ensuring geometric accuracy during assembly and high precision. It refines the processes of straightness, parallelism, and squareness, which are essential for every machine's foundation. Users can extract straightness results from parallelism and squareness tests, effectively getting two measurements in one.

While traditional tools like granite straight edges, squares, and parallels are still valuable, the XK20 system and CARTO XK20 app make these measurements easy and error-free for both skilled and inexperienced machine tool builders and assembly operators.

Straightness

The XK20 alignment laser requires minimal training to operate as its intuitive software guides users through the set up and measurement process. Its new long range straightness feature (patent pending) allows for high accuracy and repeatable measurements for large machines in any environment.

Key straightness measurements:

- Straightness of machine base/casting

- Straightness of carriages along rails

Parallelism

Parallelism is crucial for both small and large machines, ensuring linear rails and carriages run parallel to prevent poor performance. Our parallelism tools detect errors early in assembly. The XK20 system combines straightness and parallelism measurements, saving time and reducing the risk of operator error.

Key straightness measurements:

- Horizontal parallelism

- Vertical parallelism

- Vertical and horizontal parallelism

Squareness

Granite blocks are traditionally used for measuring squareness in machines. However, the square may either be too small to measure the entire machine axis or so large that it becomes difficult to move around the shopfloor. The XK20 system, with calibrated pentaprism optic, offers versatility and ease of use by measuring both large and small machine tools.

Squareness mode:

- Standard squareness

- Extended squareness

XK10 system overview

The XK10 launch is the primary laser source for most types of measurement. It is used with the M unit for geometric measurements up to 30 m. The S unit and M unit contain both transmitters and receivers which can be configured in different ways based on the measurement set-up.

The XK10's machine tool fixturing kit is designed to improve repeatability and accuracy in measurements. Measurements are taken and recorded with the XK10 display unit. This allows up to 30 hours of portable operation with the rechargeable battery.

The straightness and parallelism analysis feature in CARTO Explore creates custom reports. This provides reliable results for checking and correcting machine alignment.

Renishaw can provide calibration training from experienced engineers to ensure optimal product performance.

Key features

Flexibility - multiple measurements for different machine configurations from a single kit.

Automatic analysis - immediate measurement results, with live displays for adjustment and easy export to .xml file or CARTO.

Intuitive software - guides you through the set-up and measurement process, quickly and easily. Visit calibration software downloads for the latest version.

Wireless connectivity - ensures flexibility within the set up and measurement.

Easy fixturing - designed for repeatable, accurate results and reduces set-up time.

Rotating head - allows easy beam pointing from the launch unit with the capability to measure flatness using a series of grid points.

XK10 alignment laser accessories

Browse our range of mounting accessories and replacement parts.

XK parallelism kit

The XK parallelism kit is an additional accessory required to carry out parallelism measurements. It allows two nominally parallel straightness measurements to be carried out without moving the launch.

Accurate - 90° deflection of the laser beam. Versatile adjustments allow ease of alignment.

An optional tripod mount kit is available for use with a tripod when there is no space to directly mount the launch.

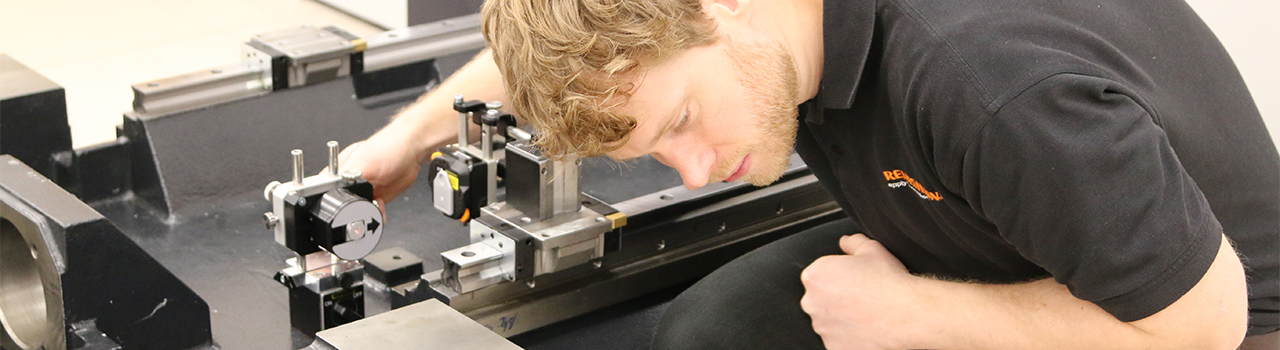

Straightness measurement

Measure vertical and horizontal straightness along an axis with the XK10 alignment laser system.

Used during the machine build process to ensure accuracy when mounting and aligning stages and guideways.

Spindle direction measurement

XK10 measures the angle at which a spindle or chuck is pointing.

This can be used for any spindle or chuck alignment, to ensure that it points in the same direction through a full 360° rotation.

Crucially, the XK10's reference mount has allowed us to capture and record accurate machine profiles, without the need for a linear guide rail. Not only has this reduced evaluation time, but it has provided greater insight into a variety of key data, which in turn will further improve the repeatability and accuracy of our measurements.

Mazak Europe, UK

Read more of our case studies

Renishaw can provide calibration training from experienced engineers to ensure optimal product performance. Discover our machine calibration and optimisation products designed to improve the performance of precision motion systems.

FAQs

What are the beam measurement ranges for the XK10 and XK20 systems?

The XK20 launch unit can measure up to 40 metres when used with the M unit. When the M unit and S unit are used for different configurations, they can measure up to 20 metres.

The XK10 launch unit can measure up to 30 metres when used with the M unit. When the M unit and S unit are used for different configurations, they can measure up to 20 metres.

What is the recommended recalibration schedule for the alignment laser system?

The recommended recalibration period for the XK10 and XK20 alignment lasers when used in a 'normal' environment is two years. To find out more, visit our calibration service, repair and recalibration web page.