FEELER benefits from Renishaw's smart manufacturing solutions

Background

The machine tool industry is evolving with manufacturers embracing the idea of intelligent production. FEELER has focused on developing smart manufacturing solutions for the global machine tool industry. They have combined machine tool production lines, automated warehousing, and robotics technology to improve the efficiency and quality of complex machining applications.

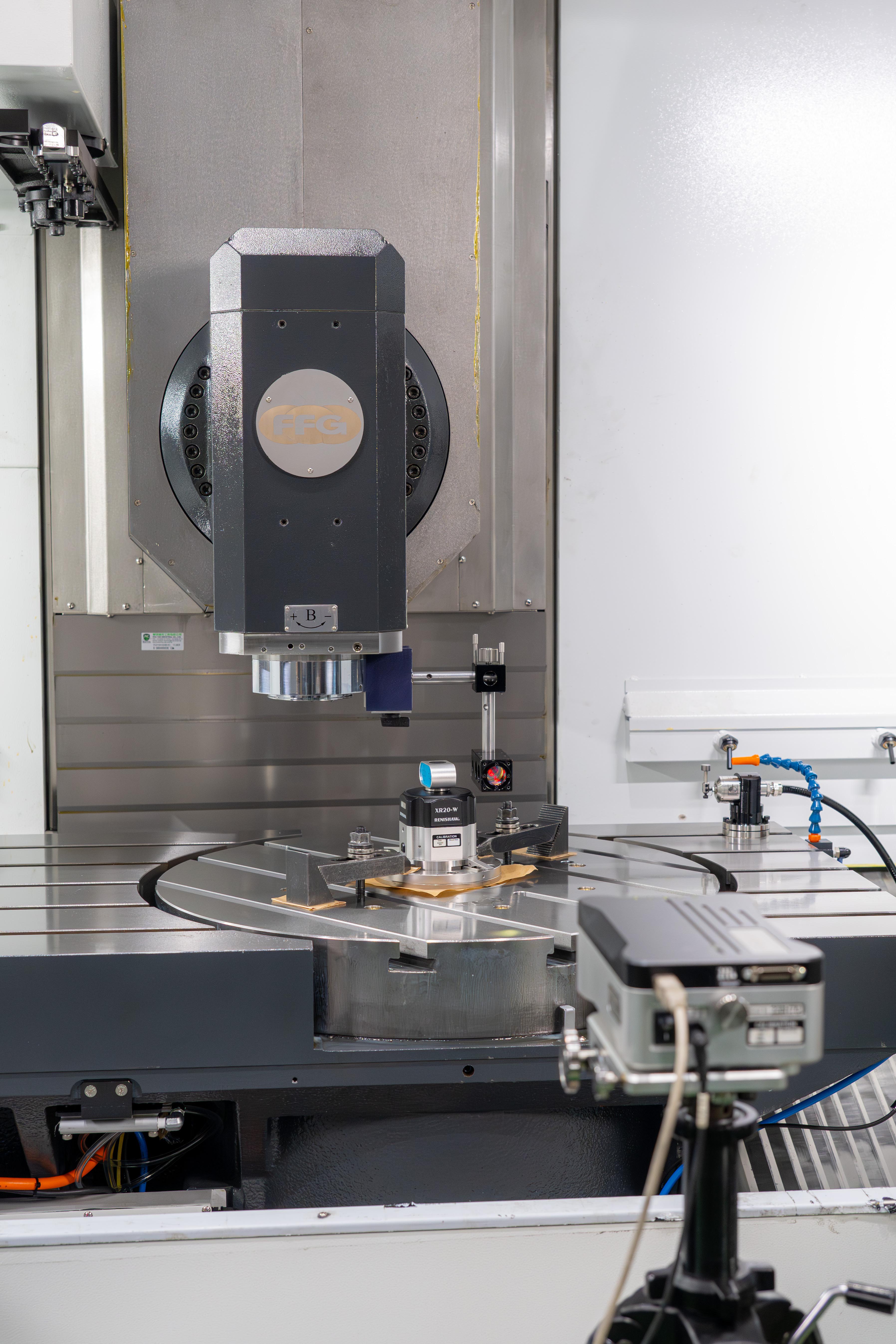

Machine tool precision is crucial to ensure that production line machining is completed right first time. FEELER uses a range of Renishaw calibration equipment to maintain the stringent accuracy requirements of its machine tools. This includes the XM-60 multi-axis calibrator for carrying out comprehensive geometric measurements on its high-precision five-axis machine tools.

For many years FEELER has relied on Renishaw's precision calibration equipment to maintain the high-quality and accuracy of its machine tools. This includes the XL-80 laser interferometer, QC20 ballbar, and now the XM-60 multi-axis calibrator.

FEELER was the first Taiwanese machine tool manufacturer to introduce the XM-60 system after its launch. The system is used for inspecting and optimising their machine tools after assembly and for final inspection before leaving the factory. It is especially used for testing the dynamic performance of the machine tools. This includes measuring the spatial performance of every axis in six degrees of freedom, analysing the dynamic straightness of machine movements and evaluating the uncertainty of positioning accuracy.

FEELER uses the XM-60 system to inspect half of the machine tools on their performance line, mostly high-end models. A report is generated after testing, which is filed as a historical record and can be supplied to the customer, if requested.

We've had success with Renishaw's XL-80 laser interferometer, so we were confident that the XM-60 multi-axis calibrator is a good fit for us. The XM-60 system improves the accuracy and stability of the machine. This helps us to be more proficient in quality control during the production process, which improves customer satisfaction and market competitiveness.

Jiaxiang Zhao, Quality Control Specialist,

FEELER

Challenge

As machined part quality improves, the industry is increasingly aware that the problems caused by spatial errors cannot be completely solved through compensation of linear errors. Guideway bending can also cause rotational errors, resulting in uneven spatial error distribution. As a result, eliminating errors at a single location does not fully remove the overall spatial errors.

That's why comprehensive geometric measurement has become an essential requirement for the industry, especially for precision five-axis machine tools. Manufacturers need to have a comprehensive understanding of the overall machine accuracy and analyse the root causes of major spatial errors to find solutions. FEELER has introduced the XM-60 multi-axis calibrator to enable comprehensive geometric measurement.

What may seem like a guideway straightness error can result from variations in the roll angle, leading to differing straightness measurements at various positions. Addressing the straightness issue while overlooking the roll angle error leads to wasted effort and produces only limited improvements.

The XM-60 system measures these geometric errors in six degrees of freedom along a linear axis simultaneously from a single set-up. This includes accurately measuring roll angle errors in any orientation. Combined with Renishaw's dedicated CARTO software, it can perform data collection and error compensation analysis. Compared to single-beam interferometers that only measure linear error and characterise the positioning accuracy at a given position, the XM-60 system offers comprehensive measurement.

Solution

The XM-60 multi-axis calibrator uses a patented roll angle optical measurement capability in all orientations that is unique to the market. This is superior to other calibrators that use electron or gravity-based design, which can only provide horizontal roll angle error measurements.

Jiaxiang Zhao, Quality Control Specialist at FEELER, commented: "The XM-60 system is packed with powerful features that allow us to understand the machine errors as a whole and their sources. By identifying all the errors, we can clearly understand the correlation between them. This enables us to build better machines and promptly develop solutions to eliminate errors."

After using the XM-60 multi-axis calibrator, FEELER's testing efficiency has improved significantly. A task that used to take three hours to complete can be done in one hour. This has reduced the resource required to run the test. Previously, FEELER measured their machines with a two-metre granite square, but segmenting the measurements reduced accuracy. However, since they introduced the XM-60 multi-axis calibrator, their measurements are more efficient and accurate.

The XM-60 system can measure in all directions in a single set-up, eliminating the need for multiple set-ups and switching between various lenses. It can measure the positioning and straightness spatial errors associated with Abbe errors, delivering more comprehensive measurement information.

FEELER owns three XL-80 interferometers and an XR20 rotary axis calibrator. The XL-80 laser is used to test mid-range models with the XR20 rotary axis calibrator, which checks the rotational accuracy of the table. By introducing the XM-60 system, FEELER has changed their roles in production as it is primarily used for high-end machine tool models.

FEELER also owns a QC20 ballbar. They use this to correct any errors found through XL-80 system testing. The QC20 ballbar is used to simulate operation and check the accuracy of machine tool movements before delivering to the customer. If necessary, corrections and compensations are made to ensure that all machines are in optimum condition.

Sometimes FEELER's engineers conduct on-site inspections for customers using the QC20 ballbar. This helps to identify and diagnose problems quickly and enables the necessary adjustments to be made.

The QC20 ballbar has optimised the overall performance of our machine tools, and significantly improved production efficiency. Renishaw's engineers provide experienced technical support. Their one-stop service improves testing efficiency by reducing errors and service delays.

Ting Che Hung, Quality Control Section Manager

FEELER