Mirrors and optics

Renishaw offer a number of optics and mirrors to provide solutions to your specific RLE laser encoder system application.

Plane mirrors

Renishaw supplied plane mirrors are manufactured on a low thermal expansion glass substrate and have a hard oxide, dielectric coating.

Features and benefits

- Thermally stable - manufactured on a low thermal expansion substrate minimises errors due to environmental variations.

- Highly reflective - highly reflective mirror surface (>97%) for the ultimate performance.

- Easy to mount - Renishaw mirror mounts provide an easy set up and alignment solution.

Dimensions

| Cross section | 25 mm x 25 mm |

| Optical aperture | 60 mm to 380 mm (10 mm increments) |

Specification

| Local flatness | < λ/10 over area 12 mm wide x 7 mm high ( λ = 633 nm) |

| Total flatness | < λ/10 per 100 mm, <0.5 µm per 500 mm |

| Cross polarisation | < 0.5% |

| Reflectivity | > 97% of incident beam |

| Material | Low thermal expansion glass |

Mirror mounts

To enable mirrors to be mounted and correctly aligned to the motion system, Renishaw offer adjustable mounts for use with mirrors up to 350 mm in length.

The mounts have a cross section of 25 mm x 25 mm, provide up to ±2.5° yaw adjustment and ±1° pitch adjustment. (Actual adjustment range is dependent on mirror length).

Renishaw supplied mirror mounts are not vacuum compatible.

Features and benefits

- Easy to align - in-built pitch and yaw adjustment to accelerate the mirror alignment process.

- Stable mounting - provide a stable foundation for the mirror whilst allowing it to thermally expand as required.

- Non-restrictive - clamping the mirror securely on two faces reduces the stress through the mirror. This minimises the risk of bending the mirror once mounted.

39 mm vacuum chamber window

The RLE fibre optic laser encoder uses interferometry to provide high resolution, linear feedback.

The RLD10-X3-DI differential interferometer is designed to mount onto the vacuum chamber wall. A vacuum chamber window allows the laser beams to pass between the detector head and the measurement mirror. Vacuum chamber windows can also be used with other interferometer head variants where the RLD detector head is required to measure within a vacuum chamber, such as RVI20 vacuum compatible interferometer.

Whilst Renishaw do not manufacture vacuum chamber windows, the 39 mm vacuum chamber window has been sourced to a custom specification to maximise the performance of the RLE fibre optic laser system.

Mounting recommendations

Renishaw recommends the following when mounting the chamber window within the chamber wall.

- The window must not be mounted under tension which could cause the window to distort and the beam to deviate from the nominal.

- An O-ring must be used on at least one side of the chamber window to create and maintain a seal in the vacuum chamber wall.

15 mm DI periscope assembly

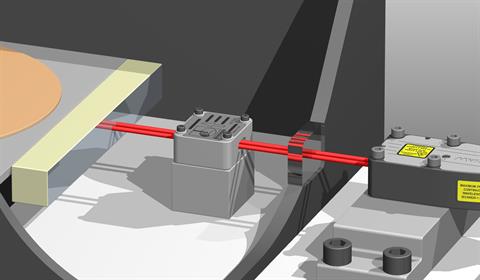

The periscope assembly increases the offset between the measurement and reference beams of the RLD10-X3-DI differential interferometer detector head.

The assembly uses two mirrors to increase the offset by 15 mm to produce a total separation of 29 mm (standard RLD10-X3-DI offset is 14 mm).

Features and benefits

- Increased offset - allows for an additional 15 mm offset between the measurement and reference beam.

- Highly reflective - using highly reflective mirrors minimises the signal strength drop between the measurement and reference beams.

- Standard mounting - the periscope maintains the standard DI detector head mounting.

RVI20 vacuum compatible interferometer

The RVI20 is a vacuum compatible interferometer assembly for plane mirrors. When used with the RLD10-A3-XX detector head it enables the entire measurement path to remain within the vacuum environment.

The RVI20 is designed to be mounted within the vacuum chamber. The laser beam passes from the RLD10-A3-XX detector head through a chamber window into the RVI20 and then onto the plane mirror.

Features and benefits

- Relative measurements - allows for relative measurements between two parts of the machine, such as tool and workpiece.

- Vacuum compatibility - compatible with high vacuum applications and is suitable for mounting within the vacuum chamber.

- High quality optics - the RVI20 contains Renishaw's high quality interferometer optical assembly normally used within the RLD detector head.

Discover our range of interferometric laser encoders providing the ultimate accuracy in linear position feedback.

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.