Navigation

RFP1 legacy probe

The REVO fringe probe (RFP1) is a non-contact structured light sensor for the REVO system on an infinitely positioning, 5-axis platform

RFP1 data is automatically stitched together in one co-ordinate frame with no need for reference markers, and can be combined with data from all other REVO-2 sensors

RFP1 data is automatically stitched together in one co-ordinate frame with no need for reference markers, and can be combined with data from all other REVO-2 sensors- Automatic exposure compensation ensures optimal data results with automatic compensation for different materials, surface colours and textures without the need for matt coatings

- RFP inspection planner generates DMIS part programs from CAD, whilst the RFP digitiser collects data from parts without CAD models as part of a reverse engineering process

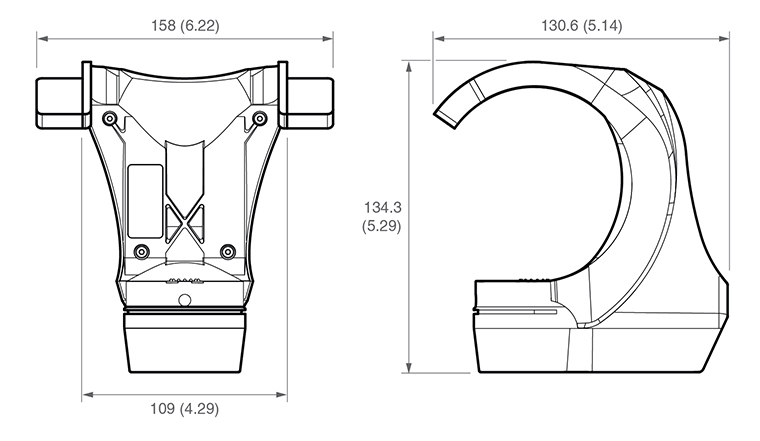

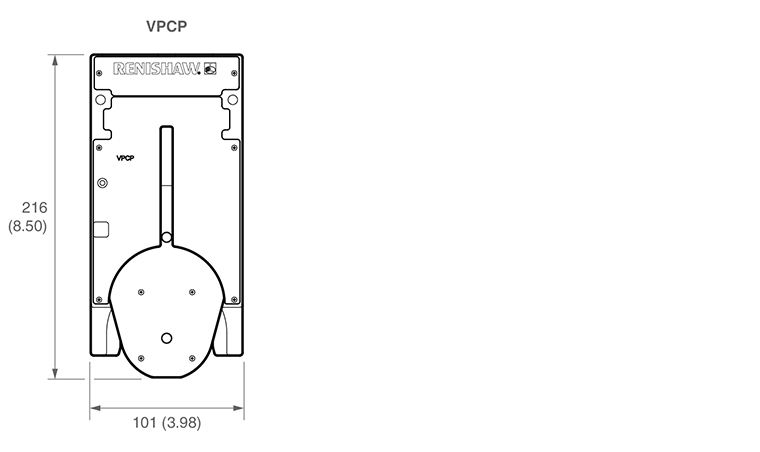

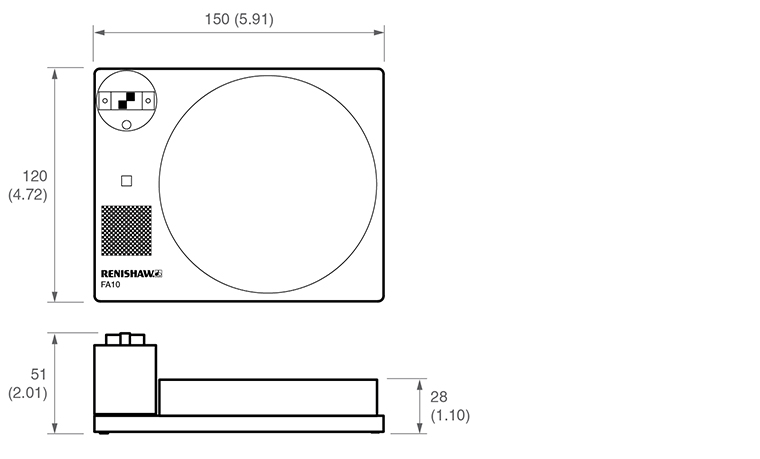

Dimensions

RFP1 REVO fringe probe

Change port

FA10 calibration artefact

NOTE: Dimensions in mm (in).

Specification

| Field of view | 50 mm x 50 mm |

| Depth of field | 20 mm |

| Stand-off | 160 mm |

Rotational capability A-axis (from REVO-2) B-axis (from REVO-2) | +120 / -5 Infinite positioning |

| XY point density (resolution) | 65 μm |

| Probe repeatability (plane) | 4 μm (2σ) |

| Probe accuracy (position error of a plane) | 9 μm |

| Measurement form error (plane) | 15 μm RMS |

| Equivalent scanning speed | 50,000 pts/s |

| Mounting | Magnetised coupling |

| Sensor type | 1/1.8” CMOS sensor |

| Projector type | Fixed sinusoidal filtering grating |

| Illumination | A wavelength of 450 nm blue LED |

| Operating modes | 3D surface point capture 2D vision measurement |

| Probe head | REVO-2 only |

| Rack port compatibility | VPCP |

| Change rack | MRS2 recommended |

| Software compatibility | UCCsuite 5.6 onwards MODUS 1.11 onwards |

| Integration | I++ DME protocol |

| Weight | 530 g |

| Operating temperature range | +10 °C to +40 °C |

| Metrology specification range | 20 °C ± 2 °C |

| Storage temperature range | -25 ˚C to +70 ˚C |

| Operating humidity | 0% to 80% (non-condensing) |

| Calibration artefact | FA10 |

| Output | Point cloud data file (.xyz) |