Ronchini Milling Technologies chooses Renishaw metrology products to enhance cutting-edge milling machines

Background

Established in 1985, Ronchini Milling Technologies (RM Technologies), produce CNC milling machines renowned for their innovative design, cutting-edge technology, and mechanical excellence.

The company specialises in manufacturing machines for milling light non-ferrous metals, technical plastics, composites, and foam materials. With a strong focus on global expansion, RM Technologies aims to establish itself in new markets and various sectors, including aerospace, marine and machine shops.

RM Technologies has selected a range of advanced metrology products from Renishaw for its CNC milling machines, including the Xtreme large plate milling machine and RoboCut automated milling cell.

Giampiero D'Egidio is the Sales and Marketing Manager at RM Technologies:

"We needed a reliable partner who could support us all over the world and provide the highest quality. We have chosen Renishaw for many reasons: global sales and technical support, reliability, and their worldwide reputation for quality. Our machines are built to give precision to customers, and Renishaw helps us achieve this."

Giampiero D'Egidio - Sales and Marketing Manager at RM Technologies

Giampiero D'Egidio - Sales and Marketing Manager at RM Technologies

Davide Campanini - R&D mechanical design engineer at RM Technologies

Davide Campanini - R&D mechanical design engineer at RM Technologies

Davide Campanini, R&D mechanical design engineer at RM Technologies, explains: "Large-format CNC machines have two big challenges: sourcing suppliers with sufficiently large machines to work on the required parts, and ensuring that these suppliers can achieve the precision and tolerances required by our machine tools."

Challenge

RM Technologies faced several engineering hurdles while striving to enhance the performance of its milling machines. Primarily, it needed to address the high precision required for large-format machines, such as the Xtreme, and streamline the complex set-up procedures traditionally needed for robotic milling cells, such as RoboCut.

Additional challenges included:

- Ensuring reliability and accuracy in automated machine tool environments.

- Reducing set-up times and material waste in robotic milling operations.

- Calibrating and certifying the machines at the end of the production process.

Solution

To overcome these challenges, RM Technologies employed a range of Renishaw products including:

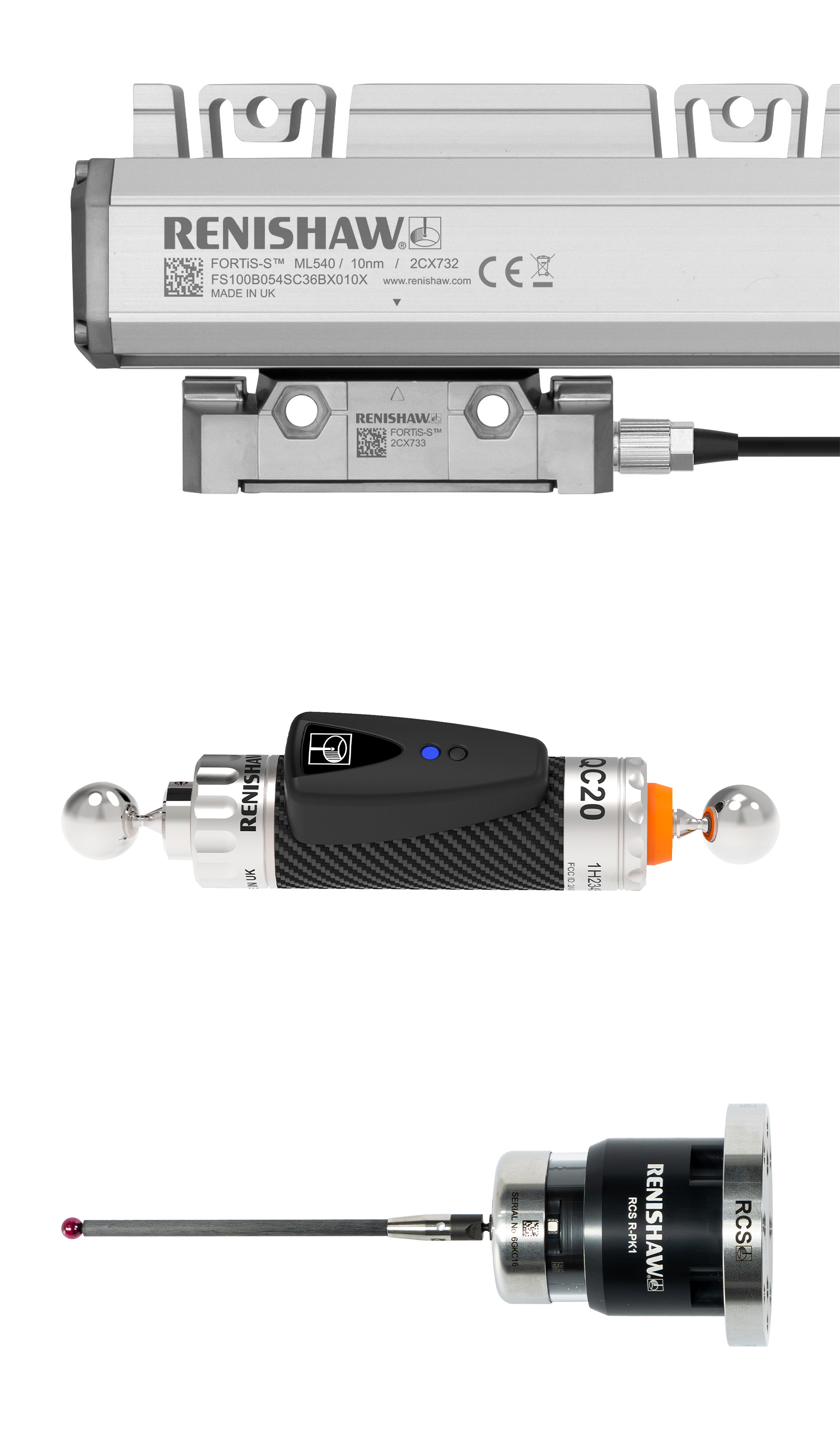

- RESOLUTE™ absolute linear encoders: Chosen for their exceptional metrology performance, enabling precise measurements at high speeds. These encoders are used on the X and Y linear axes of the Xtreme large plate milling machine.

- FORTiS™ enclosed absolute linear encoders: Selected for their high vibration resistance, ease of installation, and ability to accurately measure position even in harsh environments. These encoders are used on the Z-axis of the Xtreme large plate milling machine.

- ADTa-100 advanced diagnostic tool: Provides comprehensive real-time diagnostics for absolute encoders, ensuring optimum levels of accuracy and reliability. This tool is used to facilitate the installation and set-up of RESOLUTE and FORTiS encoders.

- RCS P-series probing system: Helps to improve set-up times, increase precision, and reduce material waste, which led to its selection for use in the RoboCut automated milling cell.

- Tool setting and probing systems: Used across RM Technologies' range of CNC milling machines to reduce set-up times and enhance in-process control.

- QC20 ballbar: Chosen by RM Technologies to certify the performance of its milling machine tools, ensuring they meet customer expectations.

- PH20 touch-trigger probe head for co-ordinate measuring machine (CMM) systems: Selected for its unique ‘head touches' feature, allowing measurement points to be taken by moving only the probe head, rather than the CMM structure.

Xtreme large plate milling machine

RM Technologies' customers demand high reliability and repeatability in their precision manufacturing, Mr Campanini says:

"Xtreme is a powerful CNC milling machine designed to set new standards for performance and precision in large plate machining and nesting. Its high power and extremely rigid design enable the machine to achieve unrivalled levels of material removal, speed, precision, and finish. We chose RESOLUTE encoders for the X and Y axes because we needed a compact readhead offering exceptional metrology performance at high speeds. For the Z axis, we selected the FORTiS-S encoder due to its accuracy, immunity to contamination, and ease of installation.

FORTiS-S enclosed encoder, QC20 ballbar and RCS P-series probe head

FORTiS-S enclosed encoder, QC20 ballbar and RCS P-series probe head

Xtreme CNC milling machine

The FORTiS encoder is installed outside the machine, so it is exposed to all the processing residues, chips, and swarf that the spindle produces. It was surprising to see how the FORTiS scale had no problems when faced with all that contamination. These encoders are also very easy to disassemble and clean. The FORTiS optical scales help maintain part repeatability by compensating for variations in mechanical precision when working in different areas of the machine."

Mr Campanini continues, "For the RESOLUTE encoders, we used the ADTa-100 Advanced Diagnostic Tool provided by Renishaw, which simplified the installation process. A Renishaw engineer provided on-site training for our staff during the initial installations.

Renishaw's absolute optical encoders help to minimise errors that could lead to material waste – especially important when working with expensive metals. Additionally, these encoders can help eliminate the need for rework parts due to dimensional inaccuracies; a common source of scrap in machining processes.”

RoboCut automated milling cell

RoboCut is a versatile robotic milling system used to produce sculptures for visual communication projects in exhibition spaces, and stage sets in television and theatre. It features a 6-axis anthropomorphic arm and a workpiece rotary table – offering maximum flexibility for producing complex designs.

Renishaw's RCS P-series probing solution for robots meets the demand for precise centring in machining operations. Before RM Technologies discovered the RCS P-series, custom probing cycles were developed using Renishaw laser calibration hardware. Although this was extremely accurate, it was time-consuming and resource intensive.

RoboCut robotic milling system

The main advantage of the robot probing system is that it allows for faster automated set-ups, with rapid part alignment and zero- point detection.

Other advantages of using the RCS P-series probing system include:

- Greater precision and repeatability: ensures precise datum detection on large and complex parts, improving overall machining accuracy and eliminating errors.

- Reductions in material waste: reduces the need for extra material to compensate for inaccuracies, resulting in significant material savings.

Bruno Henrique Grapeggia - CTO & COO Software and Robotics at RM Technologies

Bruno Henrique Grapeggia - CTO & COO Software and Robotics at RM Technologies

“RoboCut offers unparalleled freedom of movement, enabling highly accurate machining and complex design realisation. It features up to eight interpolated axes, a 14-kilowatt spindle, and a tool changer with ten positions. Setting up a robot

cell like this presents technical challenges, but our RoboCut product ensures innovative solutions for milling complex pieces while guaranteeing reduced space usage and maximum safety. We considered the Renishaw RCS P-series solution when a customer presented us with a project requiring high precision in part placement and increased throughput. With Renishaw's macros installed on our robot, we can automatically detect all datum points, align the part, and set the zero point with high accuracy before starting a machining cycle.

Before adopting the PK40+ (robot probe), we developed custom probing cycles internally. Renishaw's solution has streamlined our processes, reduced set-up times, and improved precision and repeatability. We also reduce material waste because the placement of the part is much more repeatable, allowing our customers to reduce raw material use and achieve significant savings.

Renishaw provided extensive support and training during the initial installation, which was highly appreciated by RM Technologies. We also valued their availability and the sharing of expertise from our experience in milling and Renishaw's experience in measurement systems. This partnership has been ideal for creating a winning solution."

Results

Mr Grapeggia also explains how the Renishaw QC20 ballbar is used in machine tool verification:

“The QC20 ballbar allows us to certify our machines at the end of production. We can therefore provide customers with a certificate that guarantees the machine has been tested and certified for the precision it was sold for. So, in Renishaw, we found the ideal partner.”

The adoption of Renishaw's solutions has led to significant improvements for RM Technologies machines. Its Xtreme large plate milling machine achieves high speeds and precise positioning with reduced maintenance requirements and minimal production downtime.

Renishaw probes provide precision metrology support for RM Technologies' machine tool customers.

The robust design of Renishaw's FORTiS-S™ enclosed absolute encoders on the Xtreme large plate milling machine ensures uninterrupted operation in automated environments even in the presence of liquids and solid debris contaminants. This allows for complex operations with minimal intervention. The precise position feedback from FORTiS encoders also minimises errors and material waste.

The RCS P-series probing system significantly reduced set-up times and improved overall machining precision, leading to more efficient and accurate operations of the RoboCut automated milling cell. RM Technologies' partnership with Renishaw has been instrumental in achieving their global ambitions, providing reliable and innovative solutions that meet the diverse needs of their customers.

Mr D'Egidio concludes: “Renishaw's global support and reputation have been essential for our international growth. We had been exploring the market a lot before choosing Renishaw. We are very happy with this decision because the partnership has been great. The machines have been working perfectly with Renishaw equipment. I've always considered Renishaw one of the best partners to work with.”

RCS P-series probing system in action