VAD Instrument chooses Renishaw’s UHV optical encoders for motion platforms

Vacuum technology is used in many high-precision manufacturing processes. Typical applications include semiconductor wafer inspection, wafer bonding, photolithography and thin film deposition.

Motion platforms are an integral part of these complex procedures and must be compatible with a vacuum environment.

Renishaw's TONiC™ UHV optical encoders are specially designed for use in high and ultra-high vacuum enclosures and meet the strict requirements of FPD and semiconductor process equipment. VAD Instrument, based in South Korea, manufactures a wide range of precision motion platforms for semiconductor, FPD and electronics applications.

VAD selected Renishaw's TONiC UHV encoder and RLE fibre optic laser encoder for its latest range of vacuum compatible platforms, which deliver improved motion control performance.

Challenge

To generate a high-quality vacuum, or ultra-high vacuum (UHV), the air is first removed from an enclosed space (vacuum chamber) by means of a series of pumps.

Many modern precision industrial processes are carried out in a vacuum environment in order to minimise the impact of airborne contaminants. Vacuum-compatible motion platforms consist of bearings, guide rails, leadscrews and motors that have been specially designed. The dissipation of motor heat is often problematic in a vacuum and may be strictly regulated by cooling systems. One precondition for vacuum-compatible components is that outgassing, as measured by residual gas analysis (RGA), is negligible.

Optical encoder components, such as the readhead and scale, that are installed inside a vacuum chamber have several features including high temperature resistance (>100 °C) to endure the bake-out procedures required for UHV. These include high cleanliness to eliminate surface fingerprints, oils and lubricants; air vents to ensure full venting of air spaces within the readhead; cable with PTFE insulation and silverplated copper braiding; and laser inscription rather than labels to remove adhesives.

For the end-user, careful design of in-vacuum equipment enables reductions in pumping times, better process control and higher throughput.

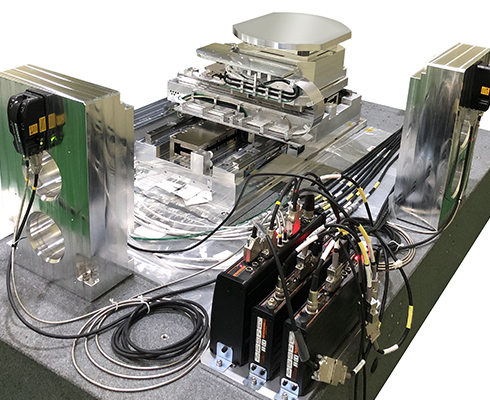

Vacuum stage, for semiconductor wafer inspection (AOI), fitted with

RLE laser encoder system

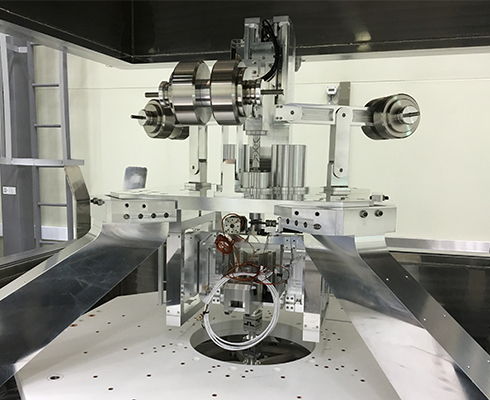

Vacuum stage for semiconductor process application

Renishaw provides us with cost-effective and high performance position feedback solutions and offers excellent technical support and regular training.

VAD Instrument (South Korea)

Solution

VAD designs and builds customised precision motion platforms and process equipment for use in a vacuum environment. Its motion control products use Renishaw's TONiC encoder systems with scales specified according to the accuracy requirements.

VAD President Mr Baek-Kyun Song explains: “Our general platform models are equipped with RTLC series steel tape scales. If advanced vacuum applications are involved, such as display panel AOI inspection equipment or semiconductor process equipment, we will specify the higher precision RELM scales. The scale is read by a vacuum-compatible TONiC readhead and is connected to an interface outside the vacuum chamber. There are many high-quality encoder products on the market, but few are also compatible with vacuum applications. Renishaw's TONiC UHV encoder delivers both excellent performance and reliability, it is our best choice.”

TONiC UHV encoders, from the cables, to the readheads, to the scales, are designed for vacuum pressures under 10-9 mbar. The TONiC UHV readhead is equipped with an RFI shielded cable, and its basic working principle, specifications and performance are the same as for the standard TONiC model. The encoder is made from cleanroom and vacuum-compatible materials and is designed to enable full evacuation of the readhead body. TONiC UHV readheads and scales have also been certified by an independent test agency using residual gas analysis (RGA) data collected on a quadrupole mass spectrometer. Specialised sealed foil packaging ensures that each TONiC UHV encoder arrives at the customer in clean room condition.

The TONiC encoder series offers a diverse range of readhead options, which can be matched with a variety of compatible scales.

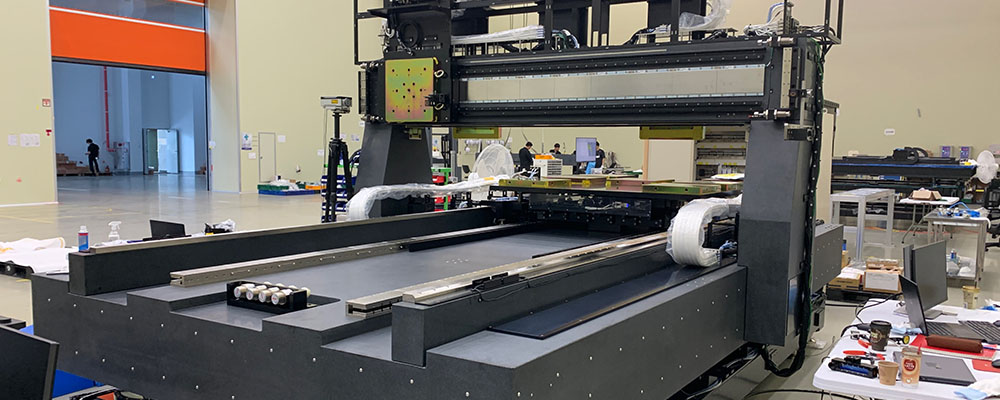

Mr Song explains VAD's criteria for selecting encoder scales: "Some of our high-end models use high accuracy RELM spar scale, which has near-zero thermal expansion, to ensure that positioning accuracy is maintained in environments with large temperature differences.

For instance, temperatures inside a vacuum chamber can often vary by as much as 100 °C from one side to the other. Renishaw's encoder products have a good reputation in the marketplace; the TONiC encoder series is often seen in applications with high-performance equipment and has been widely recognized by the industry. In addition, Renishaw's after-sales service is excellent and includes regular product bulletins. For us, the most important thing is that the delivery is punctual so that we don't lose customers due to long waits for parts."

For nanometre-level precision, VAD employs Renishaw's RLE laser encoder system for the position feedback control of an XY stage designed for semiconductor mask inspection by extreme ultra-violet light. The RLE system uses plane mirrors that are mounted on each linear axis and is suitable for vacuum applications, because the laser head can be mounted outside the vacuum chamber.

Mr Song continues: "Renishaw provides us with cost-effective and high performance position feedback solutions and offers excellent technical support and regular training. The RLE laser encoder delivers nanometre accuracy for our front-end semiconductor process equipment with the additional benefits of easy installation and setup, and short lead times."

VAD tests and calibrates its products prior to leaving the factory using Renishaw's XL-80 laser system for machine calibration and quality control. These systems are fast, extremely accurate with linear measurement accuracies of 0.5 ppm, lightweight and portable.

TONiC UHV encoder system

Results

Renishaw's TONiC encoder series, RLE laser encoder system and XL-80 laser interferometer system are combined to give VAD an advanced integrated metrology solution for its motion platforms.

In vacuum applications, the TONiC UHV encoder with 20 μm-pitch RELM (ZeroMet™) scale delivers an absolute accuracy of ±1 μm per metre and features a coefficient of thermal expansion of just 0.75 ±0.35 μm/m/°C (at 20 °C). The scale can be installed with either self-adhesive backing tape or by mechanical means to avoid adhesive degassing under vacuum.

The RLE laser encoder features exceptional resolutions down to 38.6 picometres and a system non-linearity error (SDE) as low as ±1 nm.

Mr Song concludes: “We are optimistic about the future market demand for vacuum application equipment; especially precision industrial process equipment in FPD and semiconductor manufacturing. At present, VAD is developing related process platforms for these applications.”

Stage for automatic optical inspection (AOI) of flat panel displays (FPD)