Laser encoders explained

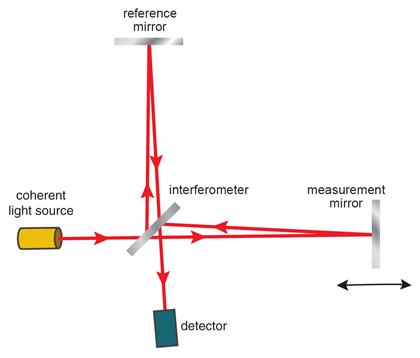

A laser encoder system adds a greater level of accuracy and precision to your measurement toolkit. Laser interferometry is a well-established method for measuring distances with great accuracy.

Renishaw's interferometric laser systems

Renishaw has been offering long and short range laser-based feedback solutions since 1994.

Our first long-range solution was the HS10 laser encoder system. It had a range of up to 60 m and was used extensively on large machine tools for aerospace, marine and other specialist applications. In 2012, we launched the HS20 long range laser, offering redesigned optics and electronics to give enhanced and more robust performance.

The RLE laser encoder series was introduced in 2001 to offer short range feedback (up to 4 m).

The RLE uses a unique and patented 'remote' laser source and optical fibre linked head to deliver enhanced metrology, reduced installation footprint and simplified installation and set-up. The system is easily configurable to suit different optical arrangements and applications.

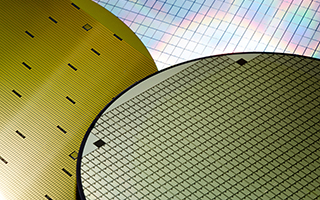

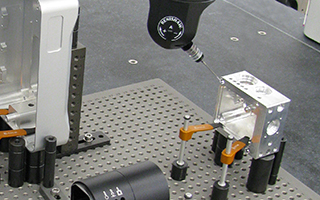

The RLE system has established itself with global manufacturers of DR and CD-SEM metrology equipment, and many other short-range applications. Its features and capabilities deliver the advantages of interferometry previously not possible. Discover more advantages to using Renishaw's laser encoders in our Why use a laser interferometric encoder article.

A wide range of accessories is available for both the RLE and HS20 systems, such as environmental compensation systems, optics and signal interfaces.

Want to know how it works?

Our How does interferometry work article explains the principles of laser interferometry and how it's used to achieve high-accuracy position feedback.

What types of applications use a laser encoder?

Laser encoders or displacement interferometers are often used in applications where the highest levels of accuracy are required.

Renishaw's laser encoder systems are suitable for a wide range of customer applications. They combine the ultimate performance of displacement interferometers with the ease of installation commonly applied to traditional tape and glass scale encoders.

Renishaw's laser encoders provide linear position measurement with high resolution and low cyclic error. Discover more about our range of interferometric laser encoders, long range lasers and accessories.

FAQs

I'm unsure of the meaning of a technical term. Is there a glossary of frequently used interferometric encoder terminology that I can refer to?

Yes, you can find definitions of the most commonly used terms in our glossary.

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.