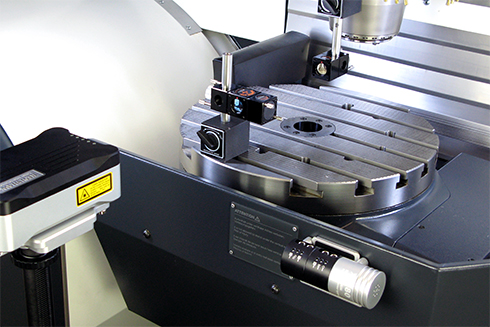

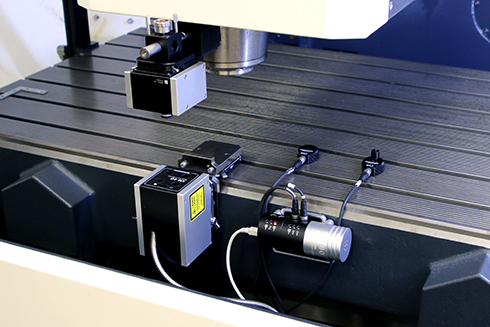

XC-80 compensator and sensors

Ensure precise and reliable laser measurement through automatic environmental compensation with the XC-80 compensator and sensors.

Accurate laser measurement over a full environmental range

Fluctuations in temperature, air pressure and relative humidity impact the wavelength of laser light emitted by laser interferometers.

With precise measurements being critical for ensuring accurate machine calibration, the XC-80 compensator provides the ideal solution. It effectively mitigates measurement errors that arise from these environmental variations.

What is an environmental compensator?

An environmental compensator such as the XC-80 compensator, reads changes in air temperature, air pressure, and relative humidity, which can affect the wavelength of the laser beam. It then calculates the refractive index of air.

The laser interferometer read-out is then automatically adjusted to compensate for any variations in the lasers wavelength. The advantage of an automatic system is that no user intervention is required and that compensation is updated frequently.

Why would you use an environmental compensator?

The XC-80 compensator is a crucial factor for linear measurement accuracy using the XL-80 laser, XM-60 and XM-600 multi-calibrators. Changes in air temperature pressure and relative humidity can affect the wavelength of the laser light and the measurement readings taken.

The 'intelligent sensors' unique to the XC-80 compensator process the readings at source and very accurately measure air temperature, air pressure and relative humidity. The XC-80 compensator uses the sensor readings to modify the nominal value of the laser wavelength to give a true value. This is used in calculations to virtually eliminate any measurement errors resulting from these variations.

Key benefits

Accuracy assured

Sensor readings modify the nominal value of the laser wavelength to give a true value.

Intelligent sensors

Accurate sensors effectively measure air temperature, air pressure and relative humidity.

Automated system

No requirement for user intervention, simplifying the process and reducing human error.

Versatile set-up

Magnetic sensor attachment and 5 m connectable sensor cables maximise usability.

Benefits and features of the XC-80 compensator

When looking to ensure accuracy, effective wavelength compensation is crucial. That is why the XC-80 compensator is a key component for maintaining accuracy over a wide range of conditions.

With interferometry explained, you can gain a further understanding of the importance of environmental compensation.

Uniform compensation - The design of the XC-80 compensator and sensors ensures uniform and extremely accurate readings over the full range of environmental operating conditions.

Frequent sensor updates - This can be done automatically every seven seconds, as indicated by LED status lights on the XC-80 compensator.

Integrated USB - The integral USB connection means there is no separate PC interface or power supply (the USB supplies the power).

Lightweight - The XC-80 compensator weighs 490 g, and combined with the XL-80 laser, weighs just over 3 kgs (including cables, XL-80 laser power supply and sensors).

Intelligent air and material temperature sensors - The integral microprocessors analyse and process the sensors output before sending digital temperature values to the XC-80 compensator. This offers more secure measurements and is a key reason why the XC-80 is so compact. It also ensures the sensors are fully interchangeable without compromising accuracy.

Up to three material temperature sensors - Attaching multiple sensors to the XC-80 compensator allows linear measurements to be normalised to a standard material temperature of 20°C.

Versatile sensor cables - The standard 5 m long sensor cables are detachable for easy replacement and can be screwed together for extended lengths on longer machines.

Discover our machine calibration and optimisation products designed to improve the performance of precision motion systems.

Additional resources

-

Brochure: XL-80 laser measurement system

Brochure: XL-80 laser measurement system

-

Application note: XL-80 laser system spares list

Application note: XL-80 laser system spares list

-

White paper: Environmental compensation of linear laser interferometer readings

White paper: Environmental compensation of linear laser interferometer readings

-

Application note: Effect of environmental compensation errors on measurement accuracy

Application note: Effect of environmental compensation errors on measurement accuracy

-

Data sheet: Traceability chart: RCU10, XC-80, RLE and HS20

Data sheet: Traceability chart: RCU10, XC-80, RLE and HS20

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.