Navigation

General safety recommendations

CAUTION: Before unpacking and installing the SP25M probe system, the user should carefully read the safety instructions below and ensure that they are followed at all times by all operators using the probe system. Use of controls or adjustments, or performance of procedures other than those specified herein may result in hazardous infra red radiation exposure.

Operators must be trained in the use and application of the SP25M probe system and accompanying products, in the context of the machine it is fitted to, before being allowed to operate that machine.

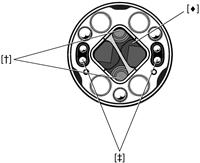

NOTE: References are made below to features indicated [†] [‡] [♦] on the illustrations shown below. Please ensure that you clearly understand all safety instructions. Familiarisation with the SP25M system components, as shown in the following sections is recommended:

- System components overview

- Schematic diagram of probe system components

- Schematic diagram of FCR25 flexible change rack

- Schematic diagram of FCR25 TC flexible change rack

The SP25M probe system has mechanical overtravel protection provided in the probe +Z axis, by a fixed bumpstop. The machine control system must therefore be able to stop the motion of the machine, in this axis of the probe, before the bumpstop is reached. If this is not the case, the user must wear eye protection during operation in case of stylus breakage.

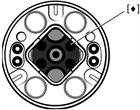

Care should be taken to ensure that the optical windows (indicated [♦]), located on both body and module, do not become damaged as they are made of glass and could cause injury.

CAUTION: Permanent magnets are used in some components of the SP25M system and associated products. It is important to keep them away from items which may be affected by magnetic fields, e.g. data storage systems, pacemakers and watches etc.

LED safety

The SP25M body contains embedded high power LED sources (indicated [†]) which emit invisible infra-red radiation. These sources are exposed when an SM25-# or TM25-20 module is not attached.

Removing the module breaks two sets of interlock switch contacts (indicated [‡]) to automatically switch off the LED power and assure user safety.

At suitable intervals, the interlock contacts should be inspected and checked to ensure that they are clean and free from airborne contamination such as dust, debris or swarf. In unlikely circumstances, such contamination could cause a short circuit of the pins and thus increase the risk of sending power to the LEDs, without a module being attached. Never connect conducting objects to, or between, the contacts. Follow the cleaning instructions in the Maintenance section.

Before inspecting, always remove the SP25M body from the probe head.

In the event of serious damage to, or a rupture of, any part of the SP25M body or scanning module outer casing, IMMEDIATELY disconnect power source, remove and do not attempt to re-use the parts, and contact your supplier for advice.

Safety illustrations

These diagrams show features, indicated [†] [‡] [♦] which are referred to within these safety recommendations.

SP25M probe body

End view showing kinematic joint to module

SP25M kinematic joint to module

SM25 scanning modules

End view showing kinematic joint to body

SP25M kinematic joint to body