Advanced laser tool setters for CNC machines

Our range of advanced laser tool setters for CNC machines provide high-precision, high-speed tool measurement and broken tool detection. Improve your process control with NC4 tool setters, suitable for all sizes and types of machine tools.

Market-leading laser tool setting technology

Dimensional accuracy and part quality during the machining process can be affected by tool wear, run-out, and breakage. Renishaw's NC4 systems allow users to address these issues.

NC4 enables the measurement of a wide variety of tools at production feeds and speeds. This helps minimise the risk of machining poor parts due excessive tool wear or breakage.

As a premium laser tool setter for CNC machines, NC4 systems are a beneficial part of any manufacturer's in-process control procedures.

Why use a laser tool setter?

Tool measurement is crucial for ensuring the precision and accuracy of machined parts. By implementing in-process, automated tool setting, tight tolerances and high-quality finishes can easily be attained.

Laser tool setters deliver reliable, non-contact, high-speed measurements with sub-micron accuracy, even in the harshest environments. They reduce the need for rework, enhance overall productivity, and lead to significant cost savings in manufacturing.

Key benefits of laser tool setters

Outstanding repeatability

Tool measurement repeatability down to ±0.1 µm 2σ.

Comprehensive measurement

Accurately measures a wide range of tool geometries.

Built for harsh environments

MicroHole™ outlet and PassiveSeal™ system protect to IPX6 and IPX8 standards.

Wide range of variants available

Variety of sizes, heights and custom options to suit the application.

The NC4 allows us to check for breakages of small tools used to make keys and other reference points on the cam, which are vital if the engine is to operate properly. If it wasn't for the Renishaw system, the machine could operate with a broken cutting tip, with disastrous results.

Ducati (Italy)

Tool setting macro software

Get the most out of your laser tool setter with our intuitive tool setting macro software.

What is the right laser tool setter for my application?

Our advanced laser tool setters can enhance a wide range of machining applications to deliver precision, automated and fast in-process tool setting. It is designed to complement our other machining control devices, such as our high-accuracy probes.

Together, they deliver the most comprehensive process control possible for a huge range of machining centre setups. If you would like assistance with finding the best in-process control system, contact your local sales team.

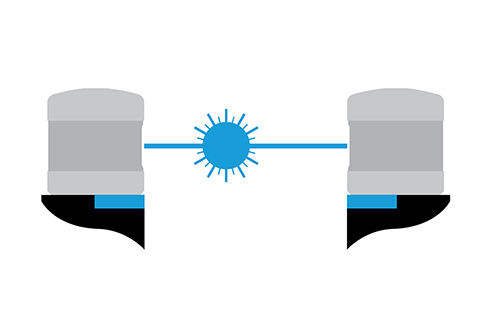

NC4+ Blue fixed systems

The NC4+ Blue range represents Renishaw's most advanced non-contact tool setting and breakage detection systems. Using patented blue laser technology and refined optical design, these compact, low-maintenance systems deliver fast, repeatable, and highly accurate measurements. Measuring cutting tools, including micro tools, is now simpler and more efficient than ever.

New to the range are the NC4+ Blue F100 systems. The F100 models achieve repeatability as low as 0.1 µm 2σ and can detect tool defects as small as 5 microns, making them our best performing units.

The F100 also introduces enhanced efficiency, with an optimised airflow design that reduces barrier air consumption by over 50%. This improvement helps lower energy usage and operational costs while maintaining exceptional measurement performance.

NC4 systems

With over a decade of proven customer experience, the original red laser NC4 system offers consistent measurement, with a repeatability of 1.0 µm 2σ.

To ensure accurate results, the NC4's built-in air blast efficiently removes machining debris and coolant from the tool before measurement.

NC4 separate systems

NC4 separate systems offer a flexible solution for complex installations. Systems can be set up in different orientations, at distances between 0.3 m and 5 m, and supplied with brackets and fittings to suit each machine installation. They use our reliable red laser technology and optical protection systems, ensuring accurate and robust performance for any application.

Bespoke NC4 systems

For custom tool setting solutions, our Custom Products team provide expert advice and design services.

Tool setting made easy with intuitive software

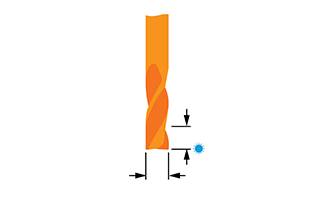

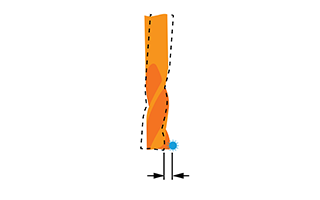

Our non-contact tool setting macro software enables length and diameter setting, radius measurement, and high-speed broken tool detection, along with advanced functionality.

Experienced users can use traditional macro code techniques, while Renishaw's user-friendly GUIs and the GoProbe appsupport new users.

Measure tool length and diameter

Measure tool length and diameter Measure the radius of a ball nose or radius-ended tool

Measure the radius of a ball nose or radius-ended tool

Measure tool run-out*

Detect broken tools

Detect chipped tool edges

Detect burrs or attached swarf

Measure tool high point and low point

Measure tool high point and low point Detect thermal growth in the spindle-axis

Detect thermal growth in the spindle-axis

Need support with NC4?

As a trusted global company, Renishaw is dedicated to providing an exceptional support service for customers.Find our readily available wide range of NC information, covering NC4, NCi-6, and Renishaw smartphone apps.

Find out more

-

Brochure: High-accuracy laser tool setting systems

Brochure: High-accuracy laser tool setting systems

-

Data sheet: NC4+ Blue non-contact tool setting system

Data sheet: NC4+ Blue non-contact tool setting system

-

Data sheet: NC4 non-contact tool setting system accessories

Data sheet: NC4 non-contact tool setting system accessories

-

Data sheet: NC4 non-contact tool setting range

Data sheet: NC4 non-contact tool setting range

-

Data sheet: NCi-6 non-contact tool setting

Data sheet: NCi-6 non-contact tool setting

-

Technical specifications: Probing systems for CNC machine tools

Technical specifications: Probing systems for CNC machine tools

-

Pocket guide: Probes for CNC machine tools

Pocket guide: Probes for CNC machine tools

Next steps

To request more information or buy, submit a contact form to speak with your local office.

Contact us