Tool setters and broken tool detectors

Achieve precise and efficient CNC machining with our automated on-machine tool setters and broken tool detectors. Explore our range of contact and non-contact solutions for CNC machines.

Broken tool detectors identify whether tools inside a machine tool are broken or intact. On-machine tool setters can automatically detect broken tools as well; however, they can also measure tool geometry and update the tool offsets on the CNC. By finding and fixing tool errors, our automated on-machine tool setters and broken tool detectors improve part quality, reduce scrap costs, and increase confidence in machining processes.

Automatically measuring cutting tools on the machine means there is no need for operators to spend time doing it manually. The risk of human error is reduced. By setting tools automatically, operators can spend time performing other activities on the shop floor.

Our on-machine tool setters and broken tool detectors work seamlessly with many types of CNC machines for milling, turning, and grinding applications. Embrace this cutting-edge technology today to enhance your manufacturing capabilities and stay ahead in a competitive market.

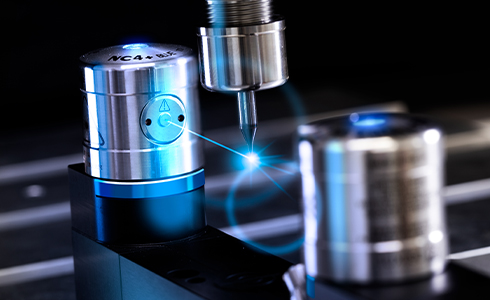

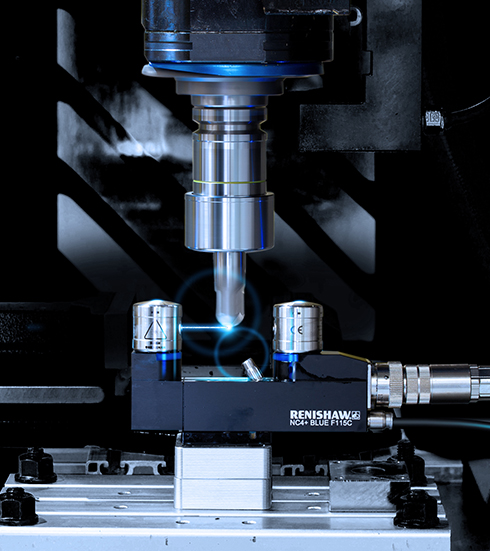

Explore our advanced laser tool setters to set tools, detect chipped edges, monitor run-out, inspect complex profiles, all without the risk of tool damage during measurement.

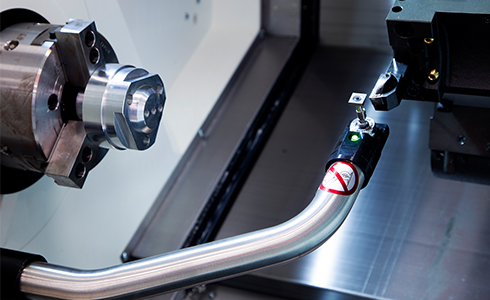

Discover our contact tool setters for tactile tool setting and broken tool detection. With a choice of transmission technology to suit your application.

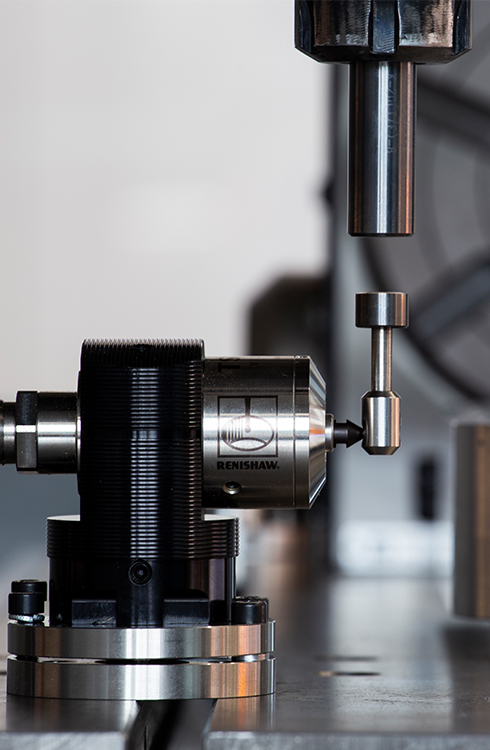

Discover our high-precision arms for tool and workpiece measurement, designed for 2-axis and 3-axis CNC machines.

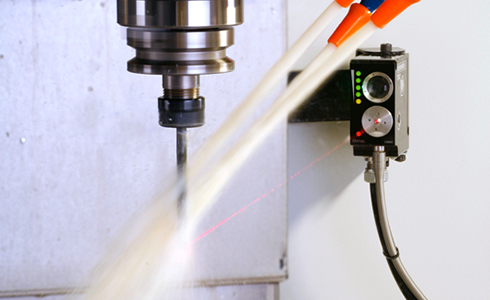

Learn about our high-speed, non-contact laser broken tool detection system. Ideal for applications when cycle time is critical.

New technologies

Discover the latest upgrade to our range of NC4+ Blue laser tool setters - the F100 and F100-10C, now equipped with cutting-edge third-generation technology.

What is tool setting and broken tool detection?

Tool setting and broken tool detection is the primary function of tool measurement systems. Tool setting is the process of measuring the dimensions and condition of cutting tools on a CNC machine. Proper tool positioning is essential for ensuring optimal performance and quality in the machining process.

Broken tool detection is the practice of detecting broken cutting tools. If a tool breaks during a machining cycle, it will continue to inaccurately machine components which could then end up as scrap. We recommend performing frequent broken tool detection cycles since tools, especially small tools, can break easily.

What are common sources of tool error?

Tool errors can have a detrimental impact on final product quality if left unmonitored. Sources of tool error include:

Tool wear: Over time cutting tools wear due to constant contact with the workpiece material. As the tool wears, its dimensions can change. This affects the accuracy of the machining process.

Incorrect tool geometry: Tool length, diameter, and radius (if using a radius-ended tool) must be correct for accurate machining. When tools are measured on an offline presetter, manual data entry errors are a possibility.

Tool defects or damage: Tools can be damaged during machining. Broken tools can lead to parts being machined inaccurately. A poor surface finish can be caused by chipped cutting edges or swarf bonding to the tool.

Incorrect tool loaded: Identifying slight differences between similar tools can be challenging. For example, determining the size of a tool nose radius can be difficult to do by eye. If an operator misidentifies a tool, the tool could be loaded into the wrong pocket.

Tool mounting issue: If there is debris between the spindle and the tool holder, or the tool is held incorrectly, then tool run-out will be a problem. Machined features on the part could be cut to the wrong size.

Manual error: Depending on how skilled the operator is, setting tools manually inside the machine might not always give the same results. The accuracy of tool setting can be hard to control because different operators have different abilities.

Thermal expansion: When the machine or tool gets hotter or colder, it can get bigger or smaller. If the machine is not thermally stable, or there is not enough coolant for the tool, the changes in size will lead to machining errors. These changes in temperature will mean that the final machined part is unlikely to be accurate.

After a detailed analysis, based on the cost to run machines, we know this equates to a saving of more than €150,000 in the first year. This is because most of the non-productive machine time taken to check tools has now been released to machine components. We have paid back the initial investment in the TRS2s in a matter of just 5 months.

SAME DEUTZ-FAHR (Italy)

The benefits of using an automated on-machine tool setter

Using a tool setter inside each CNC machine can be better than using an offline presetter. It helps with:

Real-time wear compensation: Tool length and diameter are measured on the CNC machine, just before it starts cutting. Adjustments are then automatically made to the tool size in the CNC controller, improving cutting accuracy.

Detecting broken tools in-cycle: All Renishaw tool setters can detect if a tool has snapped during machining. When you use an advanced laser tool setter, you can detect small chips in the tool edges. Preventing machining with broken tools improves workpiece quality. It also reduces the chance of the machine getting damaged, in the most severe cases.

Decision making: You can programme the machine to decide what to do based on the condition of the tool. If a tool is broken or worn, you may want to raise an alarm. If the machine is running without an operator, you might want to swap to a sister tool instead.

Space savings: Using on-machine tool setting removes the need for a separate presetter, saving valuable workshop space.

Compensation for thermal expansion: Measuring tools inside the machine, where the temperature matches the cutting conditions, ensures that the tool remains the same size during measurement and cutting, resulting in accurate machining of the part. When using a presetter, the presetter temperature may be hotter or colder than the machine temperature. This could make the tool expand or contract, providing an inaccurate tool measurement, and therefore incorrectly machining the part.

Reducing set-up time: As tool length and diameter are measured on the machine, there is no need to type the tool number or offsets in by hand. This eliminates time spent by operators setting tools on the machine, which increases the operators' productivity.

Reducing risk of operator error: As there is no need to type the tool number or offsets into the CNC controller, automated tool setters reduce the likelihood of an operator typing in the wrong values or putting the decimal point in the wrong place.

Simplifying workflow: By measuring inside the CNC machine, you no longer need to move tools back and forth between presetter and machine. This eliminates transport time and provides operators with a more streamlined workflow, enabling them to work more efficiently.

Next steps

Looking for more information or need to discuss your requirements? Submit a contact form to speak with your local office.