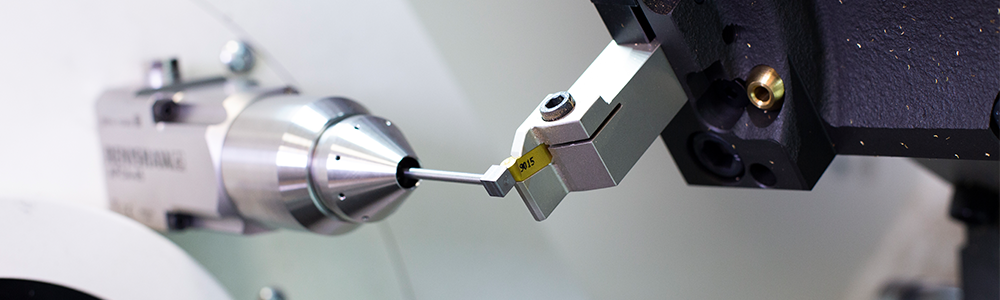

Contact tool setters for CNC machines

Improve machining accuracy

The length and diameter of the cutting tools used in CNC machines are critical parameters that need to be accurately set. If these parameters are inaccurate, even by a small margin, it can lead to errors in the final product, resulting in an increase in scrap or rework.

We offer a comprehensive range of contact tool setters, engineered for machining centres and CNC turning centres. These allow automated operation with the following benefits:

- Reduced machine downtime – Enhance operational efficiency.

- Repeatable measurement – Achieve precise tool setting with repeatability better than 1.00 µm 2σ.

- Reliable output – Minimise manual setting inaccuracies and reduce scrap.

- Breakage detection – Identify tool breakage with timely in-cycle alerts.

- Increased productivity – Automate tool setting with no specialist skills required, allowing staff to be redeployed into proactive engineering roles.

Kinematic tool setting technology

Renishaw's tool setters and broken tool detection products can help improve the efficiency of your manufacturing process.

For simple length and radius checking to broken tool detection, our contact tool setters use the same kinematic technology as our workpiece inspection probes.*

When a tool deflects the stylus, an increase in resistance is registered between the balls and rollers in the kinematic assembly.

The tool setter 'triggers' once the resistance exceeds a threshold and a signal is sent to the machine tool controller. Tool offsets can then be automatically updated or an alarm raised if the tool is broken.

The ability of the tool setter mechanism to reseat after triggering to better than 1um 2σ is fundamental for repeatability and good metrology.

Proven over five decades, kinematic technology is the preferred choice for many machine builders and end users due to its accuracy and reliability.

* With the exception of our Length Tool Setter (LTS).

With the Renishaw probes we can be confident we have correct and consistent data and we are saving in the region of 85 minutes per set-up, just on tool setting.

Quality Engineered Products (UK)

Find the right Renishaw contact tool setter for your application

| Recommended machine type | Operating range | Unidirectional repeatability | Transmission type | Compatible interfaces* | |

| OTS | Small to medium machining centres | Up to 5 m (16.4 ft) | 1.00 µm 2σ | Infrared optical (modulated) | OMM-2 or OMM-2C with OSI, OSI-D, OMI-2, OMI-2T, OMI-2H or OMI-2C |

| RTS | All sizes of machining centres | Up to 15 m (49.2 ft) | 1.00 µm 2σ | Radio - Frequency hopping spread spectrum (FHSS) | RMI-Q, RMI-QE |

| TS27R | All sizes of machining centres | N/A | 1.00 µm 2σ | Hardwired | MI 8-4, HSI or HSI-C |

| TS34 | All sizes of machining centres | N/A | 1.00 µm 2σ | Hardwired | MI8-4, HSI or HSI-C |

| LTS | All sizes of machining centres | N/A | 0.75 μm 2σ | Hardwired | N/A |

| APC | Lathes and multi-task machining applications | N/A | 1.50 μm 2σ | Hardwired | HSI or HSI-C |

*All Renishaw contact tool setters require the purchase of a compatible interface.

Length and diameter tool setters

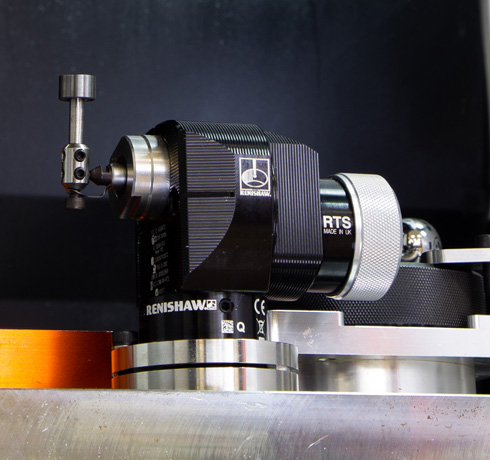

OTS

The OTS 3D touch-trigger tool setter with optical signal transmission can be used for on a wide range of tools on small to medium machining centres. It is compatible with Renishaw optical modulated receivers and can be used as part of a twin probe system. The robust and cable-free design allows freedom of table movement, ideal for twin pallet or rotary table machines.

- Proven kinematic design.

- Exceptional resistance to light interference with modulated transmission.

- Direction-adjustable infrared optical module.

- Cable-free for unrestricted machine movement and ease of installation.

- 1.00 μm 2σ repeatability.

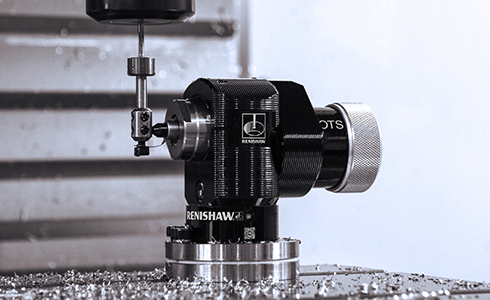

RTS

The RTS 3D touch-tigger tool setting probe with radio transmission is suitable for use on machining centres of all sizes and in applications where line-of-sight between the tool setter and receiver is difficult to achieve. The cable-free design of the RTS means it can be used stand-alone or as part of a multi‑probe system, enabling use in a wide range of applications.

- Proven kinematic design.

- Patented frequency hopping spread spectrum (FHSS), for optimal interference resistance.

- Globally recognised 2.4 GHz waveband compliant with radio regulations in all major markets.

- Cable-free for unrestricted machine movement and ease of installation.

- 1.00 µm 2σ repeatability.

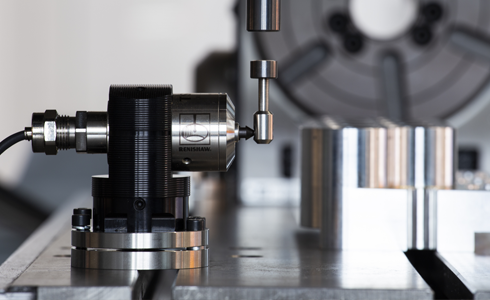

TS27R

TS27R is a versatile 3D touch-trigger tool setter with hardwired signal transmission for use on all sizes of vertical and horizontal machining centres and all gantry machining centres.

- Proven kinematic design.

- Interference-resistant hardwired communication.

- Cost-effective tool setting for all types of machining centres.

- 1.00 μm 2σ repeatability.

TS34

The compact TS34 3D touch-trigger tool setter with hardwired signal transmission offers rapid tool setting and tool wear monitoring for CNC machining centres. Available as a rear or side exit version and with a smaller footprint than the TS27R, it can be used on a wide range of tools.

- Proven kinematic design.

- Interference-resistant hardwired communication.

- Compact footprint takes up minimal space on the table.

- Robust design - the probe is protected by a swarf deflector, preventing dirt and chips from entering the system.

- 1.00 µm 2σ repeatability.

Length tool setter

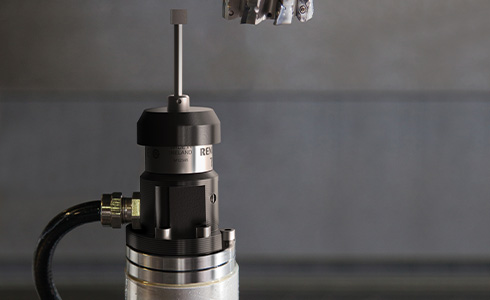

LTS

The LTS is a single-axis length tool setter, suitable for both vertical and horizontal mounting in many types of applications. As it is designed to operate within the machining environment, it is resistant to swarf or coolant ingress and prevents false triggers due to shocks or vibration.

- Plain bearing design for the highest longevity.

- Hardwired design featuring a fully integrated interface for direct connection to the machine controller.

- Integrated air blast that provides effective swarf removal when necessary.

- Robust design for operation in the harshest machining environments.

- 0.75 µm 2σ repeatability.

Lathe tool setter

APC

The compact APCA-45 tool setting probe, specifically engineered for the harshest environments found in lathes and multi-tasking machines. A robust and compact stainless steel body provides installation flexibility, enabling fitment in areas of the machine previously unsuitable for tool setters.

- Rapid measurement of turning, parting, grooving, threading, and boring tools.

- Interference resistant hardwired communication.

- Pneumatic cover that ensures the stylus is fully protected when not in use.

- Integrated air-bleed to help the stylus remain free of debris (including air blast port for customers who require tool cleaning).

- 1.50 µm 2σ repeatability.

Next steps

To request more information or buy, submit a contact form to speak with your local office.

Contact us

Downloads

Brochures

Data sheets

-

Data sheet: OTS

Data sheet: OTS

-

Data sheet: RTS (QE) radio tool setter

Data sheet: RTS (QE) radio tool setter

-

Data sheet: RTS radio transmission tool setter

Data sheet: RTS radio transmission tool setter

-

Data sheet: TS27R tool setting probe

Data sheet: TS27R tool setting probe

-

Data sheet: TS34 tool setting probe

Data sheet: TS34 tool setting probe

-

Data sheet: LTS (length tool setter)

Data sheet: LTS (length tool setter)

-

Data sheet: APCA-45 and APCS-45

Data sheet: APCA-45 and APCS-45

-

Data sheet: OMI-2 optical machine interface

Data sheet: OMI-2 optical machine interface

-

Data sheet: OMI-2T

Data sheet: OMI-2T

-

Data sheet: OMI-2C optical machine interface

Data sheet: OMI-2C optical machine interface

-

Data sheet: OMM-2C optical machine module

Data sheet: OMM-2C optical machine module

-

Data sheet: OSI with OMM-2 multiple optical probe interface system

Data sheet: OSI with OMM-2 multiple optical probe interface system

-

Data sheet: RMI-Q radio machine interface

Data sheet: RMI-Q radio machine interface

-

Data sheet: RMI-QE radio machine interface

Data sheet: RMI-QE radio machine interface

-

Data sheet: HSI high speed interface

Data sheet: HSI high speed interface

-

Data sheet: HSI-C

Data sheet: HSI-C

-

Data sheet: MI 8-4 interface unit

Data sheet: MI 8-4 interface unit

Software that makes tool setting simple

Explore our range of tool setting software and machine tool apps to quickly and intuitively program measurement cycles.

Looking for support?

Contact us or visit our technical support library for installation manuals, user guides and compliance information.