Probing and tool measurement systems for machine tools

Renishaw offers a comprehensive range of probing and tool measurement systems for CNC machine tools. Designed to improve machining accuracy and efficiency, our automated systems deliver significant cost savings and quality improvements.

Machine tool probing and on-machine tool measurement is an established best practice in the machining industry. Manually setting and inspecting tools and parts can be detrimental to machining performance and profitability. Our probing and tool setting systems help manufacturers to reduce scrap rates, eliminate machine down-time, and improve component quality.

Our solutions enable automated component set-up, in-cycle gauging, tool setting, and broken tool detection. When coupled with automatic offset updates, our technology enables you to machine with confidence, reduce set‑up times, and improve process control.

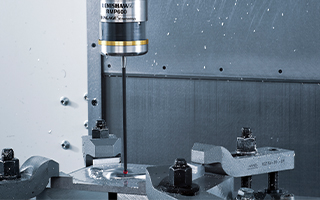

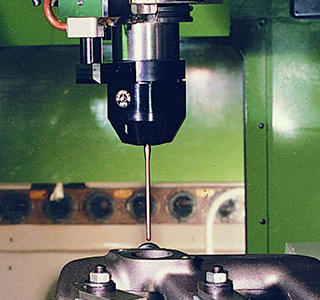

Explore our range of touch-trigger and scanning probes for workpiece set-up and inspection.

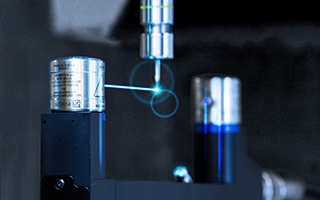

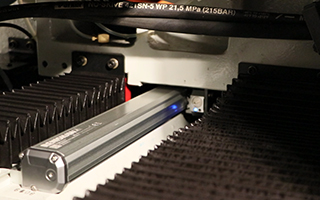

Discover our tool setting and broken tool detection systems for all types and sizes of CNC machine tools.

Maximise your probing and tool setting hardware with our flexible macro and PC-based software and apps.

Discover our machine tool maintenance and health check monitoring solutions for reliable, productive machining.

Designed to withstand harsh environments, find your enclosed optical encoder solution for machine tool applications.

Visit our technical support library for help with installation and training on machine tool hardware and software products.

What is machine tool probing and tool measurement?

Machine tool probing and tool measurement is the process of measuring the position, dimensions, and features of a workpiece or cutting tool on a machine tool. This ensures you meet required specifications and tolerances before and during the machining process.

Precise workpiece and tool measurement on a CNC machine helps to achieve accurate and consistent machining results, enhancing productivity, and minimising the risk of costly errors.

- Machine tool probes for workpiece setting and inspection gather data on the shape, size, and position of a workpiece. Use to accurately measure features of machined parts and provide fast part set-up.

- Tool setting and broken tool detection systems measure the cutting tool itself, rather than the workpiece. They establish a reference point on the cutting tool and check for any wear or breakage.

How to order

To purchase, submit a contact form to speak to your local sales team.

Alternatively, you can buy a selection of machine tool probing systems and accessories from our Online store 24/7.

The benefits of machine tool probing and tool measurement

Workpiece and tool measurement can happen before, during, and after machining tasks. By practicing this type of measurement, eliminate costly machine downtime and component scrapping. This allows you to better invest your time and money into productive machining.

- Increase throughput from existing assets; defer capital expenditure, reduce subcontract and overtime bills, and pursue additional business.

- Increase automation in setting and measurement processes; reduce human intervention and redeploy staff into proactive engineering roles. Give your machine tools the intelligence they need to make decisions for themselves, enabling extended periods of ‘lights out' machining.

- Eliminate rework and scrap; probing a workpiece at key stages of the machining process allows process parameters adjustments. This reduces part-to-part variation, thus increasing process capability and reducing non-conformance. Helping you to lower unit costs and shorten lead times.

- Keep pace with the needs of your market; automated setting using probes will allow you to set up complex components, eliminating the need for costly precision fixtures. This means you can respond quickly to new customer requirements by rapidly introducing new processes.

We were looking at several different companies for the provision of the machine probing systems we needed. We settled with just one company that we felt comfortable with and that fits perfectly with our engineering culture. That company was Renishaw. They provide good technical support, their on-site technicians are very knowledgeable, and I'd describe their equipment as top-notch.

Tigercat Industries Inc. (Canada)

Ensure right-first-time parts

An inaccurate machine cannot consistently make accurate parts. Regular machine tool maintenance and health check monitoring is essential for reliable, high-precision machining.

These types of preventative actions help to reduce sources of variation. They are the foundations of process control and ensure a consistent and efficient machining process.

Unsure about which system you need?

Use our probe selector to identify which system would best suit your machine tool set-up.

Our expertise with CNC machining in industrial manufacturing

Throughout our history, we have continuously advocated engineering, change, and innovation. Established in 1973, our first product was the touch-trigger probe. This innovative product revolutionised the capabilities of co-ordinate measuring machines (CMMs), enabling the accurate measurement of machined components.

In the mid-1970s, Renishaw introduced the first probe designed for metal cutting applications. This made automated probing for set-up and in-cycle inspection possible.

Today, our probe and tool measurement systems deliver significant quality and performance improvements throughout a wide range of applications and industries. Wherever you are in the world, with whatever machine, application, or problem, there is a Renishaw system that can transform your manufacturing production process.

Require a custom solution?

We have a dedicated custom products team that offers expert advice and design services for machine tool products. With unparalleled experience in custom-designs we are confident that we can meet your requirements, whatever the challenge.

Our offering includes:

- Custom design and manufacturing solutions, ranging from specialist styli to full probing and tool measurement systems.

- Machine surveys to find and design only the best solution for each individual requirement.

- Easy integration of standard and custom products onto your machine.

- Excellent costs and delivery times for custom products.

- Supporting of both new machine designs and retrofit requirements.

Whatever your requirement, our custom products team are here to help. Get in touch today.

Leverage your machine tool data to its full potential

Discover how our powerful smart manufacturing data platform, Renishaw Central, can optimise your machining process and increase productivity.

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.