When do I probe?

Backed by innovative technology, proven methods and expert support, Renishaw can help bring your goal of ‘green button' or ‘lights out' machining within reach.

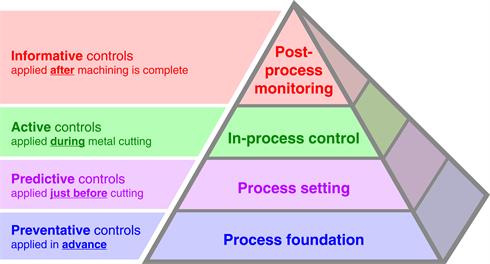

The Productive Process Pyramid™

Renishaw's Productive Process Pyramid™ provides a framework to identify process control activities at all stages of manufacture. Layers of control can be used to systematically remove variation from the machining process, helping to ensure acceptable, in-tolerance, components.

The post-process monitoring layer concerns checking the process and the finished part against their specifications. Probing has an active role to play in all but the process foundation layer.

The in-process control layer tackles sources of variation that are inherent to machining, such as tool wear and temperature variation, providing intelligent feedback to the process as machining progresses.

The process setting layer deals with predictable sources of variation such as the location of the part, the size of a tool, and offsets on the machine which could otherwise cause non-conforming components.

The process foundation layer is about providing stable conditions in which the machine will work. These are preventative controls that reduce the number of sources of variation before machining starts.

Predictive

The on-machine activities required before metal cutting can commence that help to predict if the process will be successful.

Machine setting establishes …

- Alignment of a rotary axis, indexer or fixturing elements required to position and hold components.

- Position of an indexer's centre of rotation and/or reference points on fixture elements.

Part setting establishes …

- Component identification to select the correct NC program.

- Position of a datum feature to establish a work co-ordinate system (WCS).

- Billet/component size to determine stock condition and roughing cut sequence.

- Orientation of a component (relative to machine axes) to establish the co-ordinate rotation.

Tool setting establishes …

- Length from the spindle gauge-line to establish a height offset, and to check that length is within the specified tolerance.

- Diameter when spinning to establish a tool size offset.

Active

Actions embedded within the metal cutting process that automatically respond to material conditions, inherent process variations and unplanned events, giving the best chance of a successful process.

In-cycle gauging allows …

- Metal cutting to adapt to variations in the machining process such as part distortion, tool deflection and thermal effects.

- Updating of co-ordinate systems, parameters, offsets and logical program flow depending on actual material conditions.

Broken tool detection recognises …

- Presence of a tool.

- Tool position – to ensure pull-out has not occurred.

- A broken and/or chipped tool edge.

Informative

Monitoring and reporting activities that provide information on the outcome of completed processes which can then be used to influence subsequent activities.

Process logging records …

- Events that happen during the machining process such as manual or automated changes to process parameters, offsets or co-ordinate systems.

- Interventions to the process which may have influenced the outcome.

On-machine verification enables …

- Inspection of critical features in the same environmental conditions as the metal-cutting process.

- Confidence in the stability of the machining process.

Post-process reporting allows ...

- A documented record of component conformance.

- Historical tracking of critical feature dimensions for machine condition monitoring and scheduled maintenance purposes.

Relevant machine tool literature

-

Pocket guide: Probes for CNC machine tools

Pocket guide: Probes for CNC machine tools

An easy to use pocket guide introducing Renishaw's range of probing solutions for CNC machine tools. Process control solutions.

-

Technical specifications: Probing systems for CNC machine tools

Technical specifications: Probing systems for CNC machine tools

The type of probing system that you need will depend on your machine tool and the nature of the probing application. This document focuses on the main applications for probing on machine tools. It contains an introduction to the use of probing for each application, plus guidance on the selection of the most appropriate system and technical information about each probe.