Interferometric laser encoders

Renishaw's laser encoder systems are designed for advanced motion control in applications that demand high precision in multiple degrees of freedom

Our RLE systems deliver high-performance solutions for position measurement in advanced engineering environments. Built on decades of innovation, our laser encoders offer a robust solution for accurate position measurement across a wide range of applications.

Trusted by global leaders in semiconductor manufacturing, synchrotron research, and aerospace tooling, our systems deliver the accuracy and stability needed to meet the most demanding specifications.

Expand your capabilities with our laser encoders and accessories

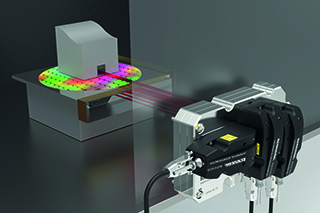

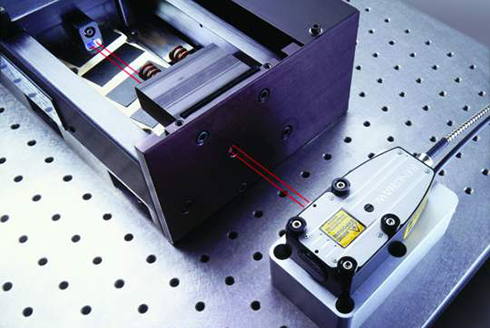

The RLE laser encoder is a unique, advanced homodyne laser interferometer system specifically designed for position feedback applications.

The multi-axis periscope enables six degrees of freedom measurement in XY stage applications using three DI interferometer heads.

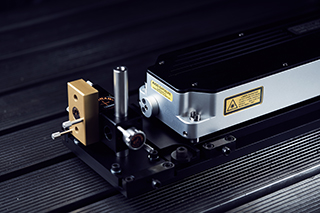

The HS20 laser encoder system combines the ultimate accuracy of a laser interferometer with the robustness needed for harsh machine shop applications.

Technical support library for interferometric laser products

Easily access guides, support documentation, and downloads for our laser encoder products.

What is a laser encoder?

A laser encoder is a displacement measurement system that uses laser interferometry to determine position with extreme precision. These systems are ideal for applications where nanometre-level accuracy, system flexibility and environmental resilience are essential.

At Renishaw, we combine the ultimate performance of displacement interferometers with the ease of installation commonly applied to traditional encoders. From this, we've gained a vast amount of experience in meeting the requirements for the motion control and accurate positioning of XY stages for different customer applications in the semiconductor, aerospace, precision manufacturing, and research sectors.

Laser encoders explained

We are dedicated to simplifying laser encoder interferometry and we know that selecting a laser encoder system is a complex process. We provide valuable information to explain the foundation behind how our products work and how they can improve your processes.

Explore laser encoders explained to get a better understanding of how Renishaw's RLE system uses a patented 'remote' laser source to deliver enhanced metrology.

Why choose Renishaw's laser encoders?

Renishaw's laser encoders are designed to support complex motion systems across a wide range of industries.

Laser encoders provide linear position measurement with high resolution and low cyclic error. They combine the measurement performance of a displacement interferometer with the ease of use and installation of traditional tape or glass scale encoders.

High accuracy

Renishaw encoders feature an innovative design and use advanced technologies to minimise errors. This means users can achieve exceptional precision and high resolution.

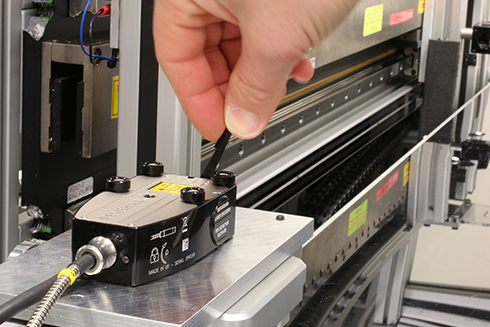

Easy set-up

The RLE and HS20 laser encoders feature robust, intuitive and user-friendly alignment, making set-up quick and easy while saving valuable time.

Highly repeatable

Renishaw's laser encoder systems deliver superior wavelength stability, ensuring consistent measurement accuracy with every application.

Installation and application support

Renishaw will be there to provide service and support, no matter where you and your customers are. We are dedicated to ensuring that you have everything you need.

Our local teams provide:

- Sales and after sales

- Training and technical support

- Spare parts and repair services

We understand that each encoder installation is different. Therefore, we offer customised detector heads to meet the specific needs of equipment manufacturer customers.

Quality and conformance

When you buy an interferometric laser encoder and its accessories from Renishaw, you are buying into a proven track record of assured quality.

Ensuring customer confidence requires quality assurance and a robust traceability record. That is why we verify all of our calibration products through national standards laboratories. This enables you to confidently provide valid documentation that demonstrates the quality and reliability of your capabilities.

Service and recalibration

Renishaw offers a full range of service options to ensure ongoing performance and allowing you to comply with quality assurance and business requirements. All laser encoder repairs are carried out by our skilled technicians. In addition to standard repairs, "Repair by Exchange" (RBE) units are also available for several items as a cost effective repair option.

Encoders for position and motion control

Position encoders can employ a range of different sensing technologies: Renishaw specialises in optical and laser encoder systems. Find your motion control solution from our range of high quality optical, magnetic and laser encoders from Renishaw.

Additional resources

Contact our sales team today

Get in contact with your local office to find out more information and speak to an expert.