Case study: Beijing Dimon Numerical Control Technology Ltd (DMNC-EDM) (pdf)

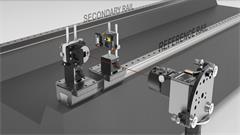

DMNC-EDM is the largest manufacturer of electrical discharge machining (EDM) machine tools in China, developing high-end, high-quality EDM machines. Critical parts produced in-house must undergo 100% inspection, but traditional contact measurement CMM systems lack the capability to measure complex features such as small apertures. To meet their inspection needs, they required a versatile coordinate measuring machine (CMM). Renishaw's AGILITY CMM and REVO® 5-axis multi-sensor system provide the necessary flexibility, with automatic switching between tactile scanning, touch-trigger, ultrasonic, vision, and surface finish measurement, ensuring comprehensive and accurate inspections for DMNC-EDM complex parts.

This type of file requires a viewer, freely available from Adobe

Latest items

- Renishaw's extended range of shop floor inspection solutions at EMO Hannover 2025

-

Inspection Plus software for DMG MORI machining centres with Fanuc/Meldas controllers with SupaTouch optimisation

Inspection Plus software for DMG MORI machining centres with Fanuc/Meldas controllers with SupaTouch optimisation

- Renishaw India debuts robot calibration at Automation Expo 2025

- Renishaw champions International Women in Engineering Day with STEM outreach programme in Welsh schools

-

AMS7003 - Additive manufacturing for aerospace

AMS7003 - Additive manufacturing for aerospace

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.