Case story – ANT REVO – Parts on multi-axis machines (jpg)

File size: 3.43 MB

Language: Language Independent

Dimensions: 3189 x 2028 px

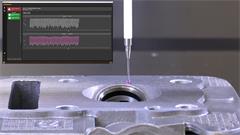

In 2008, when aerospace sub-contractor ANT Industries carried out a study on its production processes with the aim to make improvements, it was clear that inspection was a major bottleneck. “There were thousands of non-productive hours a year where parts were either in inspection or waiting to be inspected. These are expensive parts without any value being added”, says Shaun Rowley, ANT’s Manufacturing and Sales Director.

Latest items

- Renishaw additive manufacturing helps British cyclist Matthew Richardson beat 200m world record

-

Section 430(2B) Companies Act 2006 Statement – Allen Roberts - 21 August 2025

Section 430(2B) Companies Act 2006 Statement – Allen Roberts - 21 August 2025

-

TONiC™ Functional Safety T3x3x RTLC20-S linear encoder system

TONiC™ Functional Safety T3x3x RTLC20-S linear encoder system

-

DSi dual readhead angle encoder system

DSi dual readhead angle encoder system

-

TONiC™ Functional Safety T3x1x RELM20 / RSLM20 linear encoder system

TONiC™ Functional Safety T3x1x RELM20 / RSLM20 linear encoder system

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.