Case study: Special purpose machine manufacturer invests in Renishaw alignment system to expand its capabilities (pdf)

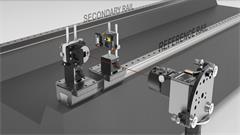

To ensure that it could deliver the best results for large-scale customer projects, specialist machine manufacturer Metecno Oy, worked with global engineering technologies company, Renishaw, to implement a geometric error measurement system. By investing in Renishaw’s XK10 alignment laser system, Metecno Oy was able to bring more quality assurance processes in-house, meeting specifications for new customers, whilst expanding its apabilities to deliver high quality machines.

This type of file requires a viewer, freely available from Adobe

Other languages

Suomi , Français , Nederlands , 中文(繁體) , 한국어 , Italiano , Português , Español , 中文(简体) , SlovenščinaLatest videos - Machine calibration and optimisation

Latest items - Machine calibration and optimisation

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.