LeanWerks case sudy (jpg)

File size: 357 kB

Language: Language Independent

Dimensions: 1000 x 500 px

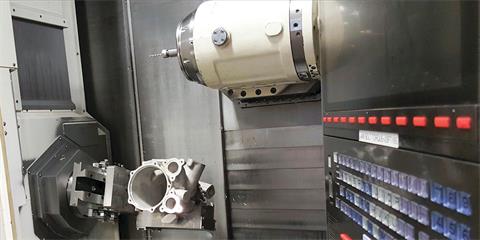

Due to the size of this piecework, the turn-mill’s Y-axis travel doesn’t enable its spindle to reach all areas of the part to be machined. To mitigate this, the fixture LeanWerks developed uses a dovetail slide to enable the fixtured part to be slid and re-clamped in an accessible position. Subsequent probing routines determine the true position of the repositioned part.

Other versions

1401×912

jpg

Latest videos - Machine tool probes and software

Latest items - Machine tool probes and software

-

Contact turning tool setting cycles for Brother SPEEDIO M140X controls

Contact turning tool setting cycles for Brother SPEEDIO M140X controls

-

Compliance information for machine tool probing systems without radio transmission

Compliance information for machine tool probing systems without radio transmission

-

Compliance information for machine tool probing systems with radio transmission

Compliance information for machine tool probing systems with radio transmission

-

Inspection Plus for maching centres using simultaneous probing - Siemens 840D

Inspection Plus for maching centres using simultaneous probing - Siemens 840D

-

Inspection cycles for Okuma machining centres when using an L-shaped stylus

Inspection cycles for Okuma machining centres when using an L-shaped stylus

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.