News release: Laser calibration at the speed of light (doc)

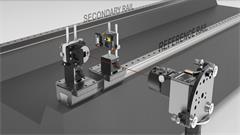

The word “laser” implies “light speed” for the casual listener, but witnessing a bi-directional laser calibration run on just one linear axis of a CNC mill conjures up a completely different image – that of something less than the speed of light. However, a technique that takes advantage of a feature in Renishaw's XL-80 laser interferometer reduces settling time to just 250 milliseconds after each incremental axis move, cutting calibration times by 85-95 percent. In addition to reducing downtime on critical production assets, this methodology better reflects axis positioning accuracy under actual cutting conditions, where moves are fast and there is virtually no settling time before tool engagement with the work.

This type of file requires a viewer, freely available from Microsoft

Latest videos - Machine calibration and optimisation

Latest items - Machine calibration and optimisation

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.