Case study: Gear manufacturer achieves consistent quality with automated robot cell (pdf)

File size: 1.27 MB

Language: English

Part number: H-2000

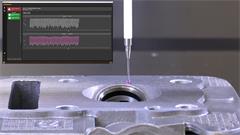

Gear and gearbox manufacturer Katsa Oy commissioned Flexmill Oy to design and build a robotised cell to finish-machine and deburr gears ranging in size from 50 mm to 1.5 m diameter. The bespoke, turnkey cell incorporates Renishaw RMP60 probes, mounted on custom-designed tool holders, which an ABB robot uses to collect vital part-location data before finishing and deburring operations commence.

This type of file requires a viewer, freely available from Adobe

Latest items - Machine tool probes and software

-

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

-

Contact tool setting software for Brother B00/C00/D00 controllers

Contact tool setting software for Brother B00/C00/D00 controllers

-

OMI-2 optical machine interface

OMI-2 optical machine interface

-

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Inspection Plus software for Fanuc/Meldas Y-axis lathes

-

H-2000-3904-01 Radio probe battery life comparison

H-2000-3904-01 Radio probe battery life comparison

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.