Probing basics - Benefits of automated broken tool detection (mp4)

File size: 130.85 MB

Language: English

Dimensions: 1920 x 1080 px

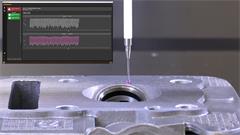

Identifying broken tools during the machining process is crucial to avoid excessive rework and the scrapping of components. Our TRS2 and on-machine tool setters can identify broken tools during the machining process and automatically initiate corrective action. For example, sound an alarm, call an operator or change to a sister tool.

Latest items - Machine tool probes and software

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.