Case study: Machine tool probing increases productivity for Australian machine shop (pdf)

File size: 415 kB

Language: English

Part number: H-5650-0059

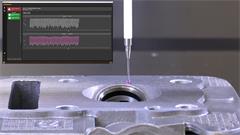

When Australia-based machine shop, Hammond Engineering, found that manually setting workpiece positions was time consuming and difficult to repeat, it looked to the potential of on-machine probing. Since using Renishaw’s OMP40-2 optical transmission probe, the company has experienced faster set-up times and higher levels of productivity.

This type of file requires a viewer, freely available from Adobe

Latest items - Machine tool probes and software

-

Next generation Blue laser technology

Next generation Blue laser technology

-

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

-

Contact tool setting software for Brother B00/C00/D00 controllers

Contact tool setting software for Brother B00/C00/D00 controllers

-

OMI-2 optical machine interface

OMI-2 optical machine interface

-

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.