Case study: Sewtec Automation - Machining capacity up 850% with just 80% more machines (docx)

File size: 18 kB

Language: English

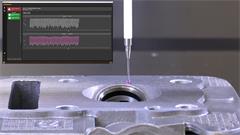

Sewtec Automation, a world leading supplier of production and packaging systems for the fast moving consumer goods sector, has dramatically increased machining output by adding 5 new HAAS machine tools with Renishaw touch probes, and a new system of shift work.

This type of file requires a viewer, freely available from Microsoft

Latest items - Machine tool probes and software

-

Next generation Blue laser technology

Next generation Blue laser technology

-

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

-

Contact tool setting software for Brother B00/C00/D00 controllers

Contact tool setting software for Brother B00/C00/D00 controllers

-

OMI-2 optical machine interface

OMI-2 optical machine interface

-

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.