Case study: Sewtec Automation - Machining capacity up 850% with just 80% more machines (docx)

File size: 18 kB

Language: English

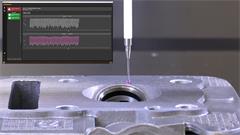

Sewtec Automation, a world leading supplier of production and packaging systems for the fast moving consumer goods sector, has dramatically increased machining output by adding 5 new HAAS machine tools with Renishaw touch probes, and a new system of shift work.

This type of file requires a viewer, freely available from Microsoft

Latest videos - Machine tool probes and software

Latest items - Machine tool probes and software

-

Inspection Plus software for DMG MORI machining centres with Fanuc/Meldas controllers with SupaTouch optimisation

Inspection Plus software for DMG MORI machining centres with Fanuc/Meldas controllers with SupaTouch optimisation

-

AxiSet™ Check-Up with auto update: macro software for Doosan SMX machines (Turn/Mill machine configuration)

AxiSet™ Check-Up with auto update: macro software for Doosan SMX machines (Turn/Mill machine configuration)

-

AxiSet™ Check-Up with auto update for Arumatic-Mi controllers

AxiSet™ Check-Up with auto update for Arumatic-Mi controllers

-

Reporter for Okuma

Reporter for Okuma

-

Set and Inspect for Okuma

Set and Inspect for Okuma

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.