Case study: Ducati - Ducati relies on tool breakage detection (pdf)

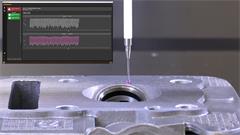

Ducati has realised that the machining of valuable components for its Desmodromic engines must be carefully controlled. Different tools are used hundreds of thousands of times during the course of a year, with the constant risk of a chipped or broken tool being picked up from the magazine, which would result in serious problems. This has been solved using a Renishaw tool breakage detection system based on innovative non-contact laser technology.

This type of file requires a viewer, freely available from Adobe

Latest videos - Machine tool probes and software

Latest items - Machine tool probes and software

-

Inspection Plus software for DMG MORI machining centres with Fanuc/Meldas controllers with SupaTouch optimisation

Inspection Plus software for DMG MORI machining centres with Fanuc/Meldas controllers with SupaTouch optimisation

-

AxiSet™ Check-Up with auto update: macro software for Doosan SMX machines (Turn/Mill machine configuration)

AxiSet™ Check-Up with auto update: macro software for Doosan SMX machines (Turn/Mill machine configuration)

-

AxiSet™ Check-Up with auto update for Arumatic-Mi controllers

AxiSet™ Check-Up with auto update for Arumatic-Mi controllers

-

Reporter for Okuma

Reporter for Okuma

-

Set and Inspect for Okuma

Set and Inspect for Okuma

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.