Case study: Primo™ system helps SuMax Enterprises to reduce part set-up time by 90% (docx)

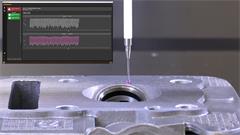

Maintaining the wall thickness of pump bodies and reducing the part setting time for manufacturing steering worm shafts is an important task for SuMax Enterprises Pvt Ltd, situated in Pune, India. It was made easy following installation of a Renishaw Primo™ system with Primo Radio Part Setter and Primo Radio 3D Tool Setter which has helped the company reduce part set-up time by 90% and eliminate scrap (previously 12%) caused by machining.

This type of file requires a viewer, freely available from Microsoft

Other languages

中文(简体)Latest videos - Machine tool probes and software

Latest items - Machine tool probes and software

-

Inspection Plus software for DMG MORI machining centres with Fanuc/Meldas controllers with SupaTouch optimisation

Inspection Plus software for DMG MORI machining centres with Fanuc/Meldas controllers with SupaTouch optimisation

-

AxiSet™ Check-Up with auto update: macro software for Doosan SMX machines (Turn/Mill machine configuration)

AxiSet™ Check-Up with auto update: macro software for Doosan SMX machines (Turn/Mill machine configuration)

-

AxiSet™ Check-Up with auto update for Arumatic-Mi controllers

AxiSet™ Check-Up with auto update for Arumatic-Mi controllers

-

Reporter for Okuma

Reporter for Okuma

-

Set and Inspect for Okuma

Set and Inspect for Okuma

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.