Case study: Hewland Engineering Ltd - Complex tool setting at the speed motor sport demands (doc)

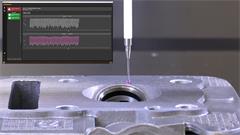

Renishaw’s automatic tool setting and tool breakage detection systems recently installed at Hewland Engineering Ltd, are proving to be highly successful in raising productivity of transmission part manufacture for motor sport vehicles worldwide. Hewland has also used the Renishaw QC10 ballbar to provide the quality assurance requested by customers, by guaranteeing the performance of its machines.

This type of file requires a viewer, freely available from Microsoft

Latest items - Machine tool probes and software

-

Next generation Blue laser technology

Next generation Blue laser technology

-

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

-

Contact tool setting software for Brother B00/C00/D00 controllers

Contact tool setting software for Brother B00/C00/D00 controllers

-

OMI-2 optical machine interface

OMI-2 optical machine interface

-

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.