Case study: On-machine user interface boosts productivity of mould base manufacturing (pdf)

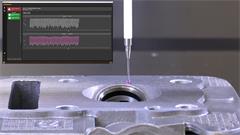

The market for mould base assemblies used in plastic injection moulding is changing. Plastic part makers are producing increasing varieties of short-run products in all kinds of different sizes, shapes and finish – each requiring a custom-made mould base. As a leader in precision mould base manufacture, GM Enterprise needed to ramp up its production throughput to meet rapidly rising customer demand. It needed to increase capacity and reduce lead times, but it also needed to avoid introducing human error.

This type of file requires a viewer, freely available from Adobe

Other languages

中文(繁體) , 中文(简体) , Español , Slovenščina , Italiano , 日本語 , hrvatski jezik , srpski jezikLatest items - Machine tool probes and software

-

Next generation Blue laser technology

Next generation Blue laser technology

-

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

-

Contact tool setting software for Brother B00/C00/D00 controllers

Contact tool setting software for Brother B00/C00/D00 controllers

-

OMI-2 optical machine interface

OMI-2 optical machine interface

-

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.