Case study: Renishaw reduces machining time for aerospace impeller manufacturer (pdf)

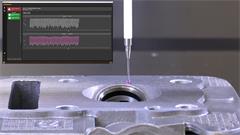

Honeywell Aerospace, part of global commercial and consumer engineering conglomerate Honeywell, produces a large number of the impellers and blisks used in commercial aeroplanes. The impellers, which are essentially radial and axial compressors, rely on a workpiece datum being maintained throughout the machining process to ensure that they are suitable for use. If the workpiece datum point is not maintained, the impeller will be considered incompatible and will require rework, repair or scrapping entirely.

This type of file requires a viewer, freely available from Adobe

Other languages

中文(简体) , 한국어 , 中文(繁體) , Slovenščina , 日本語 , hrvatski jezik , srpski jezik , Italiano , EspañolLatest items - Machine tool probes and software

-

Next generation Blue laser technology

Next generation Blue laser technology

-

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

Contact tool setting cycles for 2 and 3-axis lathes with Fanuc controllers (including rotating tool setting)

-

Contact tool setting software for Brother B00/C00/D00 controllers

Contact tool setting software for Brother B00/C00/D00 controllers

-

OMI-2 optical machine interface

OMI-2 optical machine interface

-

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Inspection Plus software for Fanuc/Meldas Y-axis lathes

Didn't find what you were looking for?

Tell us what you couldn’t find and we will do our best to help.